Product Classification

Tel/Wechat/Whatsapp

Model:

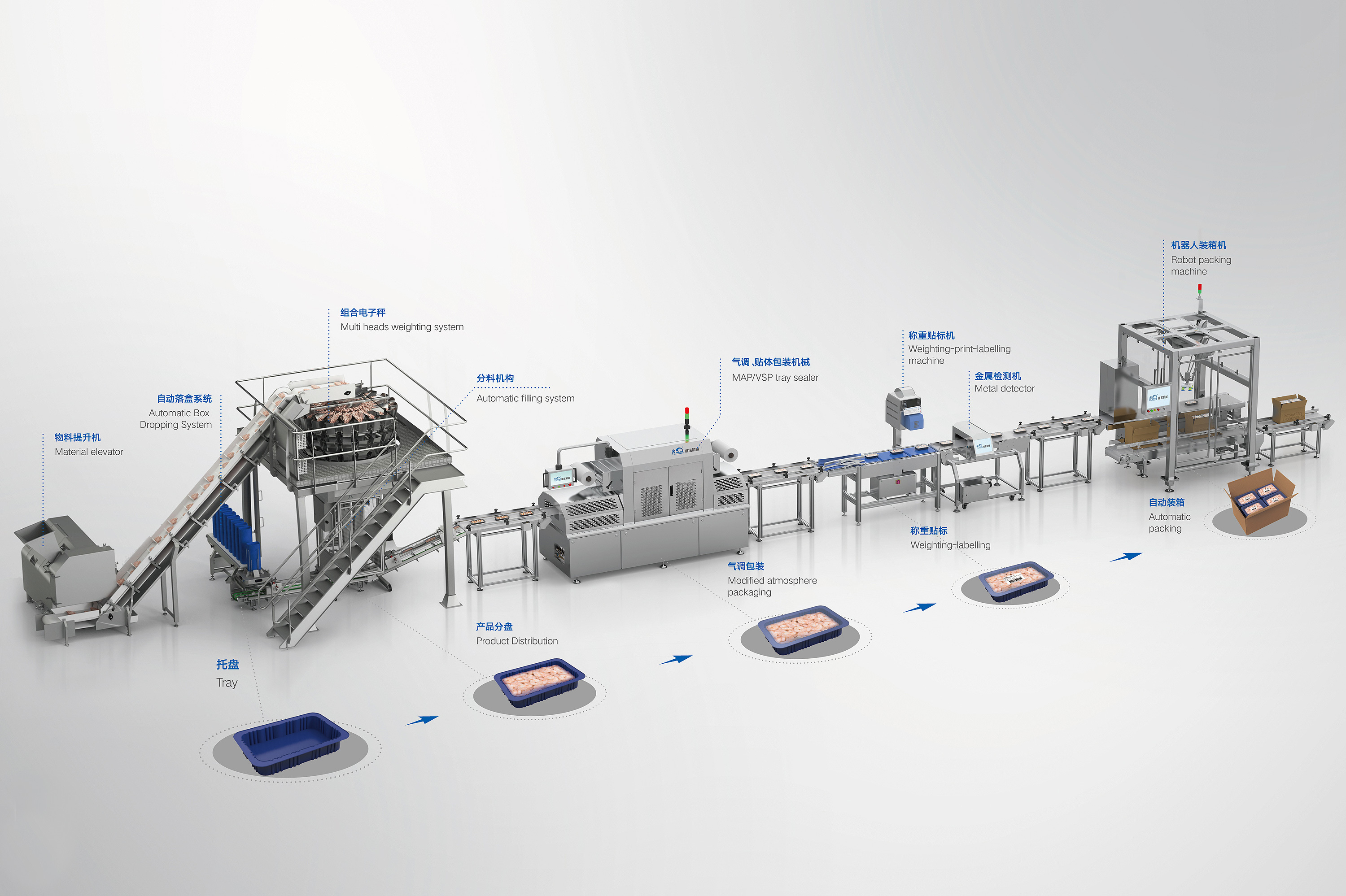

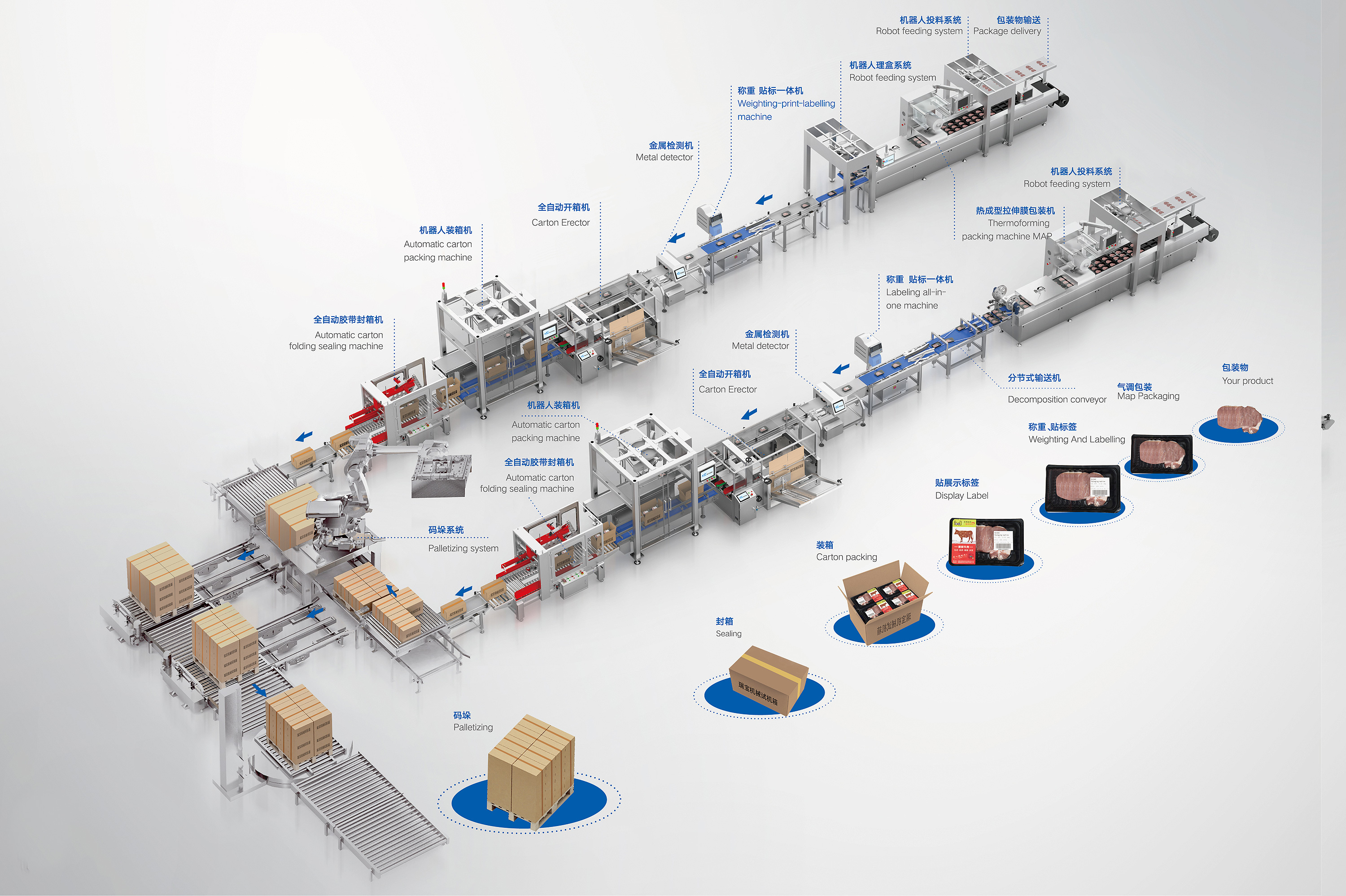

Suitable for food, meat products, medicine, electronics and other industries

Keywords:

Parallel robot grasping system

Category:

Product Center

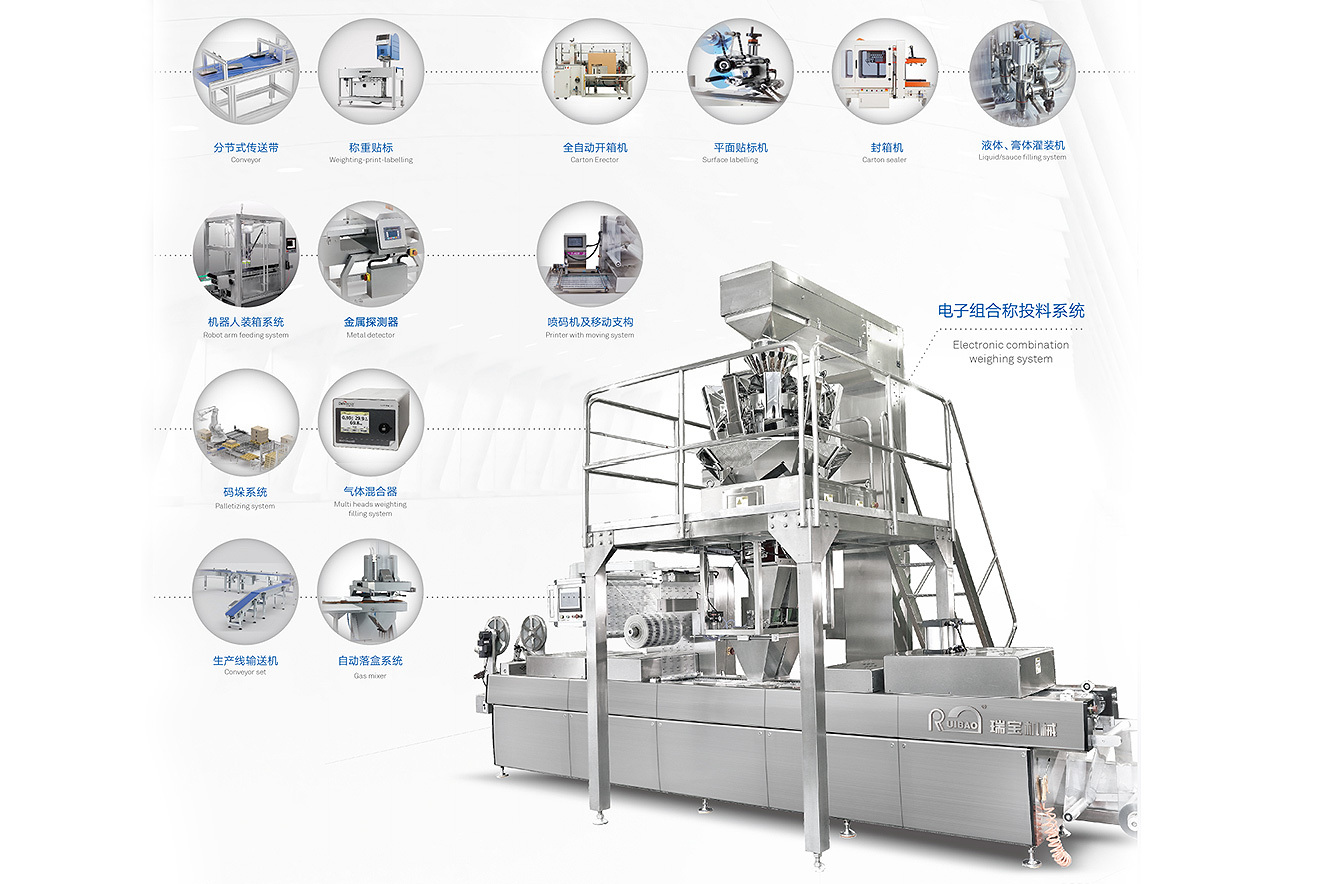

Packaging Solutions

The thermoforming vacuum packaging machine is an advanced packaging equipment which is widely used in food, pharmaceutical, chemical and other industries. It extends the shelf life of food and preserves its freshness by adsorving the Plastic Sheet on the mold after being soft by heating and using vacuum air extraction to extract air inside the packing bag, which leads to the formation of a vacuum packing bag.

EMAIL:

Tel/Wechat/WhatsApp:

Packaging Materials:

Capacity:

Packaging Technology:

The thermoforming vacuum packaging machine is an advanced packaging equipment which is widely used in food, pharmaceutical, chemical and other industries. It extends the shelf life of food and preserves its freshness by adsorving the Plastic Sheet on the mold after being soft by heating and using vacuum air extraction to extract air inside the packing bag, which leads to the formation of a vacuum packing bag.

The working principle of the thermoforming vacuum packaging machine is to form the bottom of the packaging bag by heating the plastic sheet so that it is limed and adsorbed on the mold. Then, after placing the food inside the packing bag, the air inside the packing bag is removed by a vacuum pump, and the final cap forms a vacuum packing bag. This can effectively prevent moisture and food deterioration, prolong the shelf life of food, and maintain the freshness and taste of food.

The parallel robot realizes automatic separation, handling and upper and lower grabbing of materials through visual identification and positioning, and has the advantages of agile and high speed, high positioning accuracy, improved work efficiency, labor saving, avoiding secondary pollution of materials, etc.

• Robot according to customer requirements packaging speed, material weight, work space diameter, choose different models. (different material characteristics and shapes, can be customized material gripper)

• Suitable for food, meat products, fruit, cheese, medicine, electronics and other industries.

Specifications |

Bat800-S3 | Bat1100-S3 | Bat1100-S3 | Bat1600-S6 | Bat1300B-S50 /S60 | |||||||||||||

| Rated load | 3kg | 3kg | 3kg | 6kg | 50kg~60kg | |||||||||||||

| Working space diameter | 800mm | 1100mm | 1100mm | 1600mm | 1300mm | |||||||||||||

| Number of axes | 4 | 4 | 4 | 4 | 2 | |||||||||||||

| Repeated positioning accuracy | ±0.08mm | ±0.08mm | ±0.08mm | ±0.1mm | ±0.02mm | |||||||||||||

| Four-axis angle repeat positioning accuracy | 0.2° | ±0.2° | ±0.2 | ±0.2° | ||||||||||||||

| Maximum speed | 6m/s | 10m/s | 10m/s | 10m/s | 2m/s | |||||||||||||

| Power supply voltage | Three-phase AC380V ± 10%,50/60HZ | |||||||||||||||||

| Rated power | 3.4KW | 3.4KW | 3.4KW | 4.6KW | 3.9KW | |||||||||||||

| Protection level | IP54 | IP54 | IP54 | IP54 | IP54 | |||||||||||||

| Weight | 120kg | 160kS | 160kC | 190kg | 200kg | |||||||||||||

Leave us a message

SAF Coolest v1.3.1.1 设置面板 HMZSX-ZXJW-OQAQE-AAA

无数据提示

Sorry, the current column is being updated, stay tuned!

You can look at other columns or go backHome Page