Product Classification

Tel/Wechat/Whatsapp

Model:

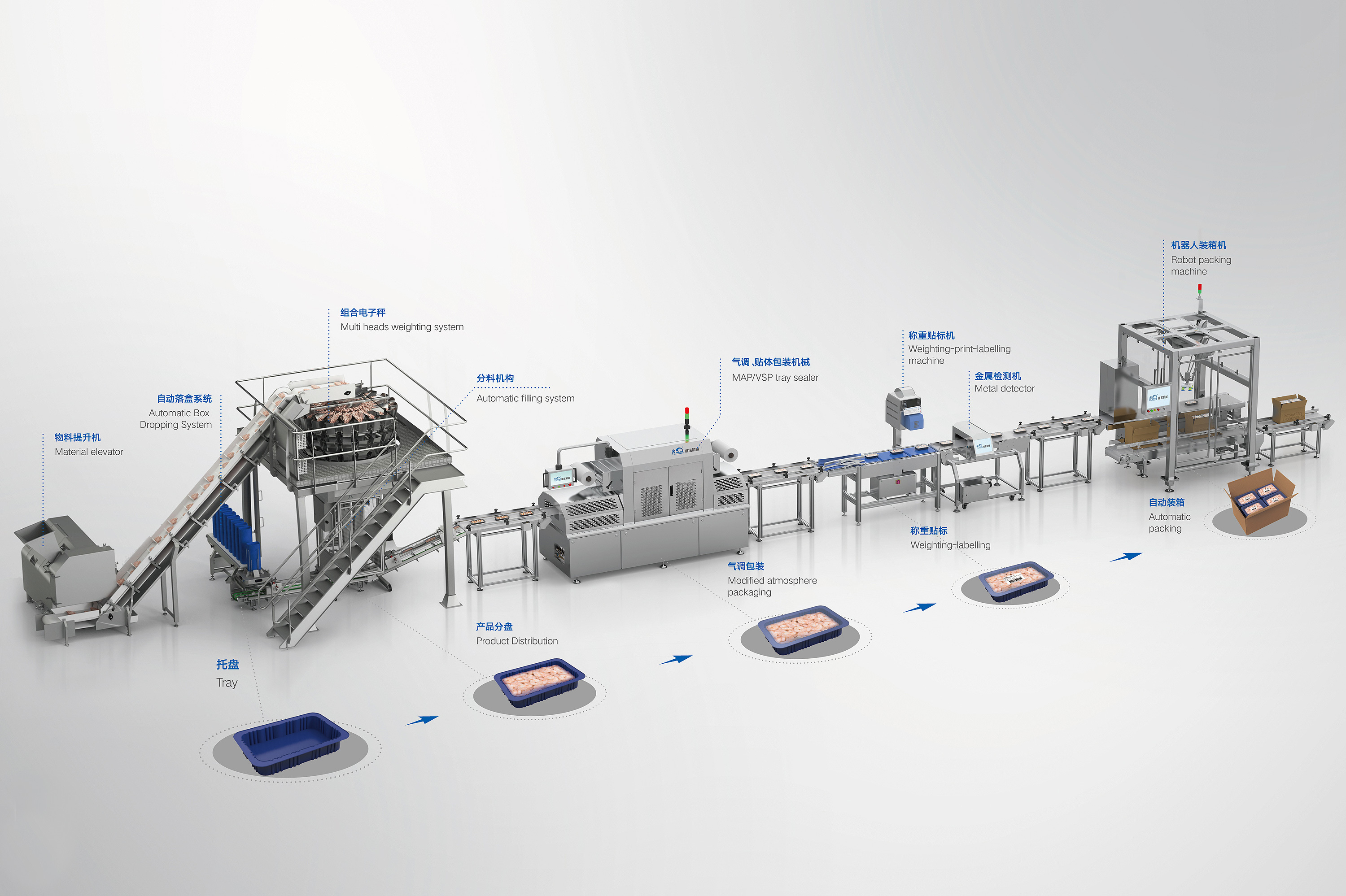

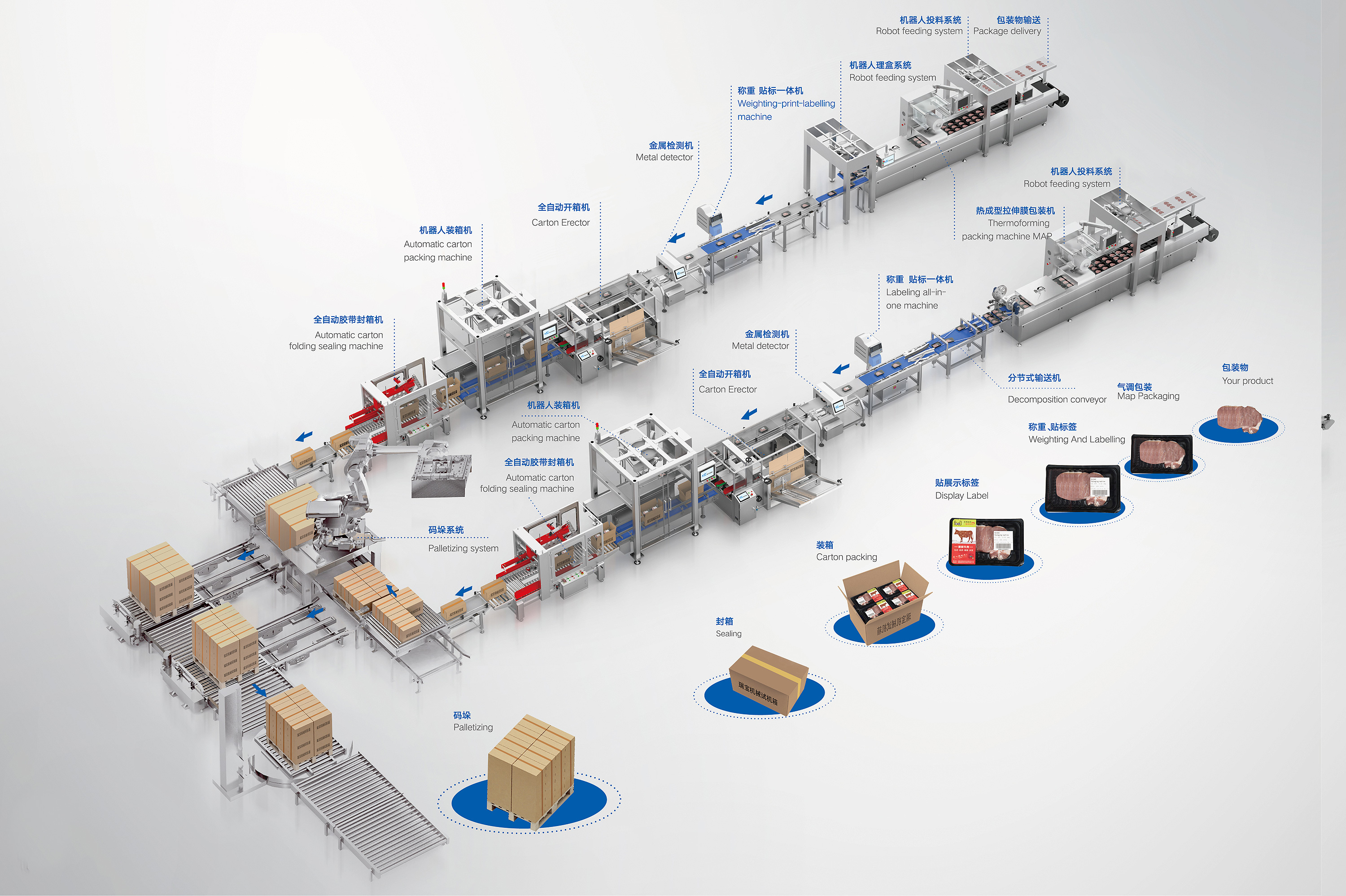

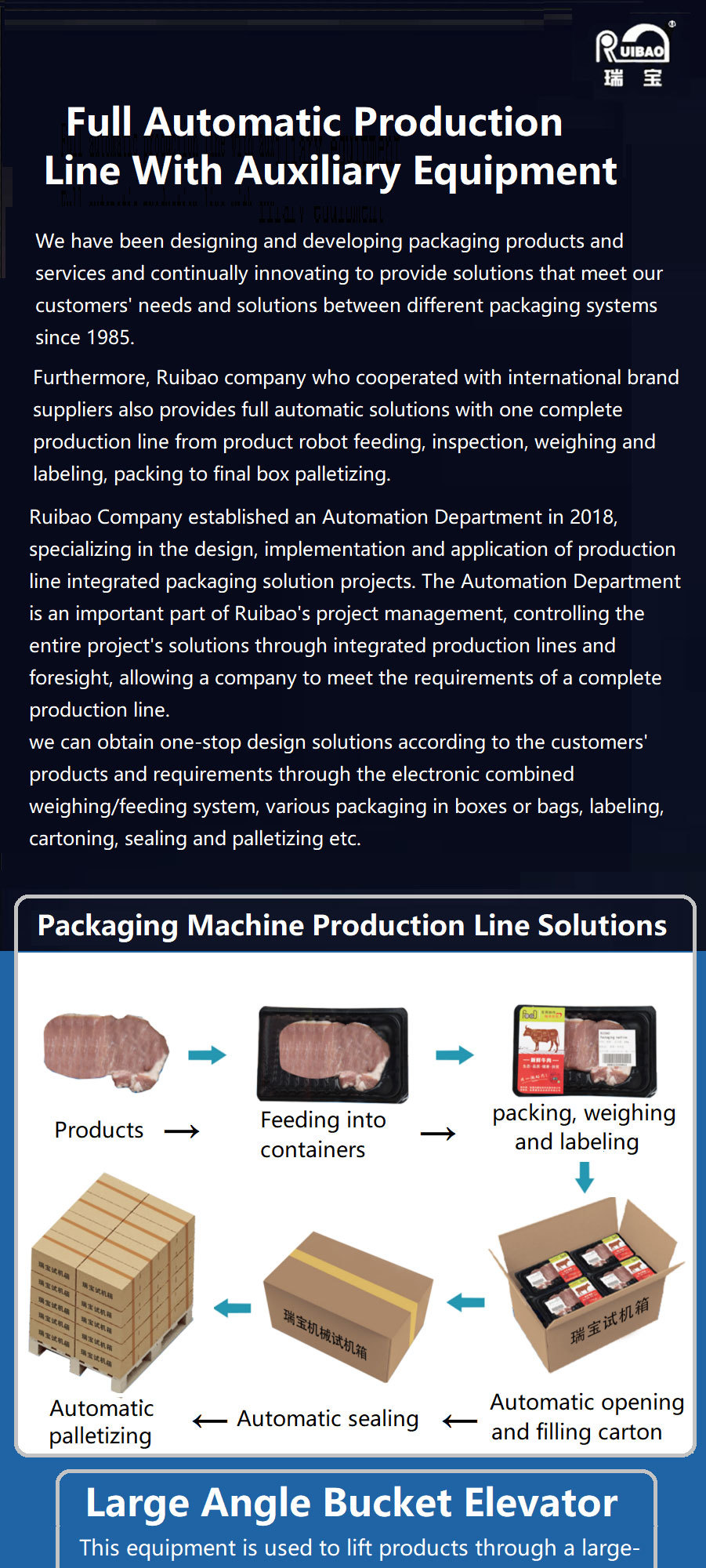

In 2018, RUIBAO established the "Automation Division", which specializes in the "Production Line Integrated Packaging Solution" project to design, implement and apply. The automation division is an important part of RUIBAO's project management, which controls the entire project solution by integrating production lines and components. enable a company to meet the requirements of a complete production line.

Through the electronic combination weighing/feeding system → (boxed or bagged) various packaging → labeling → packing → packing → sealing → palletizing, etc., the design scheme is obtained in one stop according to the customer's materials and requirements.

Keywords:

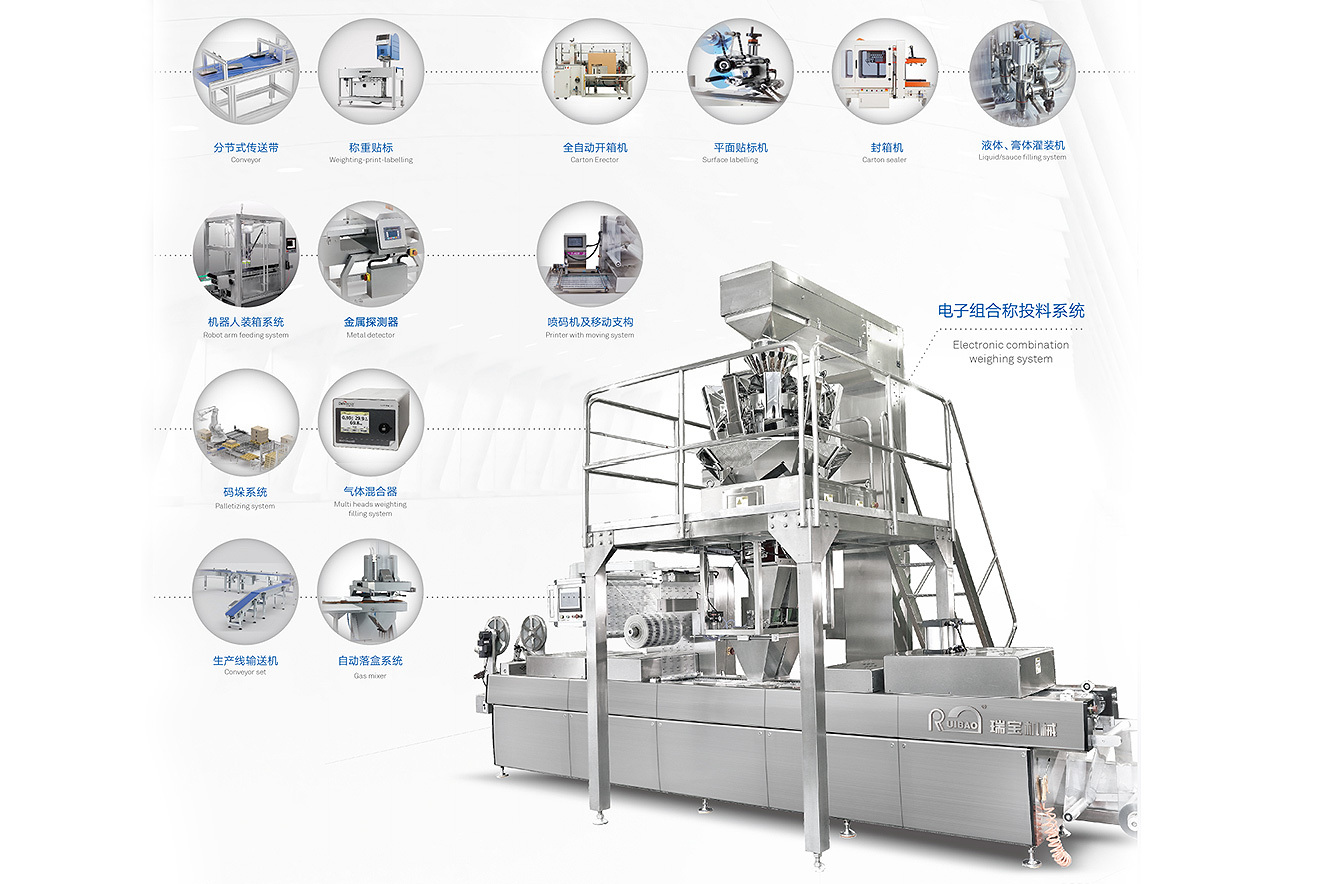

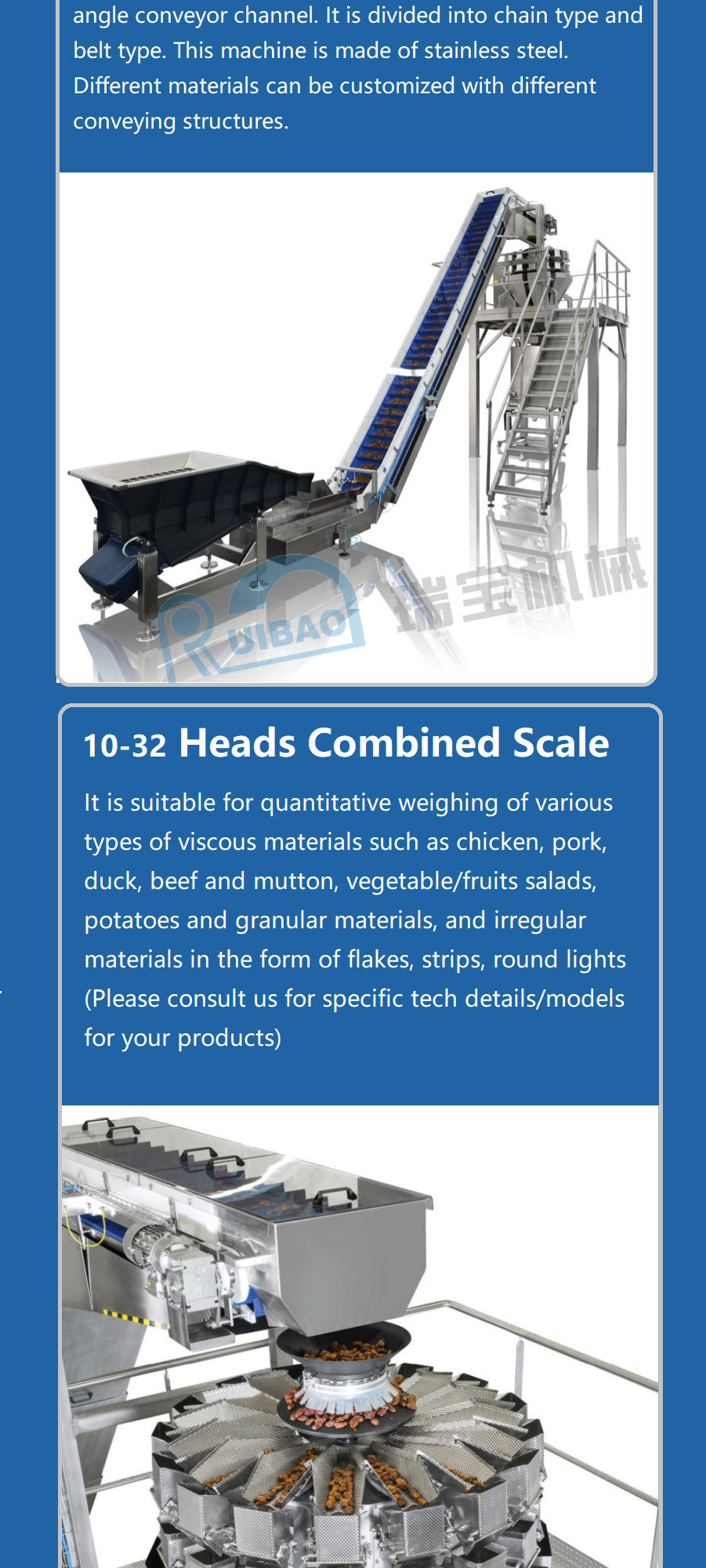

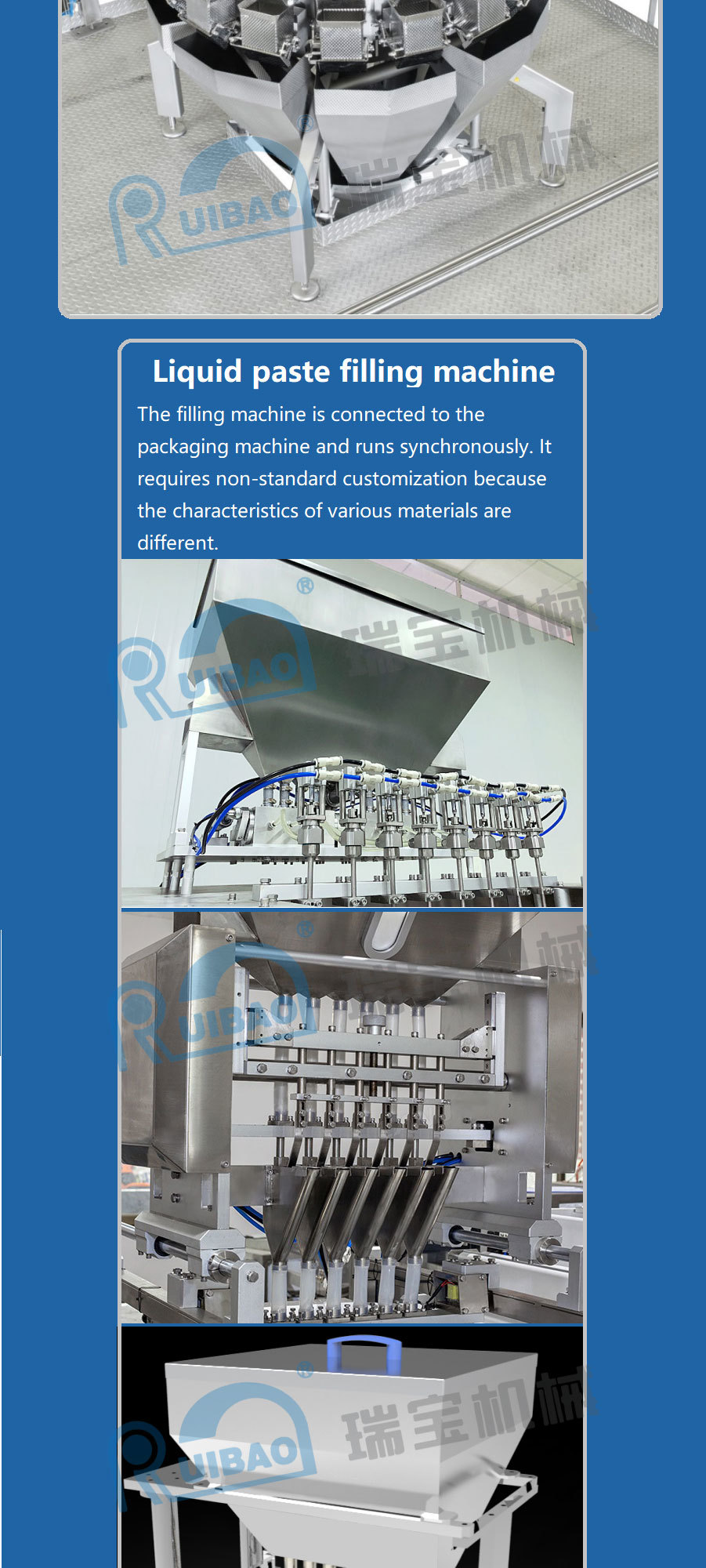

Automatic production line auxiliary equipment

Category:

Product Center

Packaging Solutions

The thermoforming vacuum packaging machine is an advanced packaging equipment which is widely used in food, pharmaceutical, chemical and other industries. It extends the shelf life of food and preserves its freshness by adsorving the Plastic Sheet on the mold after being soft by heating and using vacuum air extraction to extract air inside the packing bag, which leads to the formation of a vacuum packing bag.

EMAIL:

Tel/Wechat/WhatsApp:

Packaging Materials:

Prefabricated bag,Prefabricated box,Cardboard,Roll film

Capacity:

High,Medium,Low

Packaging Technology:

Vacuum,Modified atmosphere,Fit,Balanced atmosphere,Natural seal,Heat Shrinkage,Cling film

The thermoforming vacuum packaging machine is an advanced packaging equipment which is widely used in food, pharmaceutical, chemical and other industries. It extends the shelf life of food and preserves its freshness by adsorving the Plastic Sheet on the mold after being soft by heating and using vacuum air extraction to extract air inside the packing bag, which leads to the formation of a vacuum packing bag.

The working principle of the thermoforming vacuum packaging machine is to form the bottom of the packaging bag by heating the plastic sheet so that it is limed and adsorbed on the mold. Then, after placing the food inside the packing bag, the air inside the packing bag is removed by a vacuum pump, and the final cap forms a vacuum packing bag. This can effectively prevent moisture and food deterioration, prolong the shelf life of food, and maintain the freshness and taste of food.

Since 1985, we have been designing and developing packaging products and services and constantly innovating to provide solutions to meet customer needs in the connection between different packaging systems: thermoformed stretch film packaging, vacuum body packaging, modified atmosphere packaging, vacuum shrink packaging, etc. for your personalized customization and configuration needs. In addition, Ruibao also provides fully automatic solutions, together with international brand suppliers supporting auxiliary equipment to form a complete production line. From the product feeding system → (boxed or bagged) various packaging→ weighing/labeling → packing → packing → packing → stacking to the final packing box, etc.

• RUIBAO company, in 2018 set up the "Automation Division", specializing in the "production line integrated packaging solutions" project, to design and implementation and application. The automation division is an important part of RUIBAO's project management, which controls the entire project solution by integrating production lines and components. To enable a company to meet the requirements of a complete production line. According to the customer's materials and requirements, one-stop access to design solutions.

The following content allows you to know more about the parameters and functions of auxiliary equipment or consult our customer service personnel to serve you

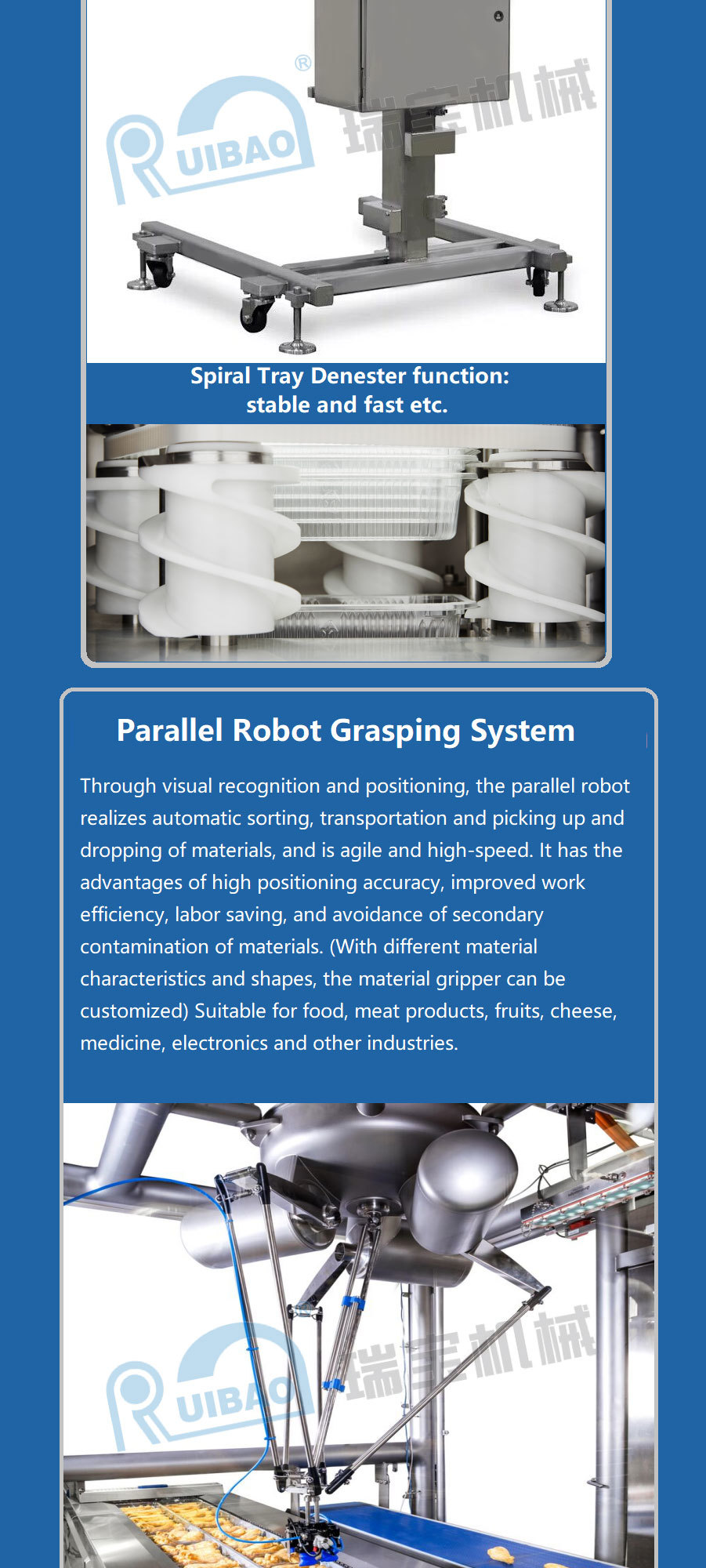

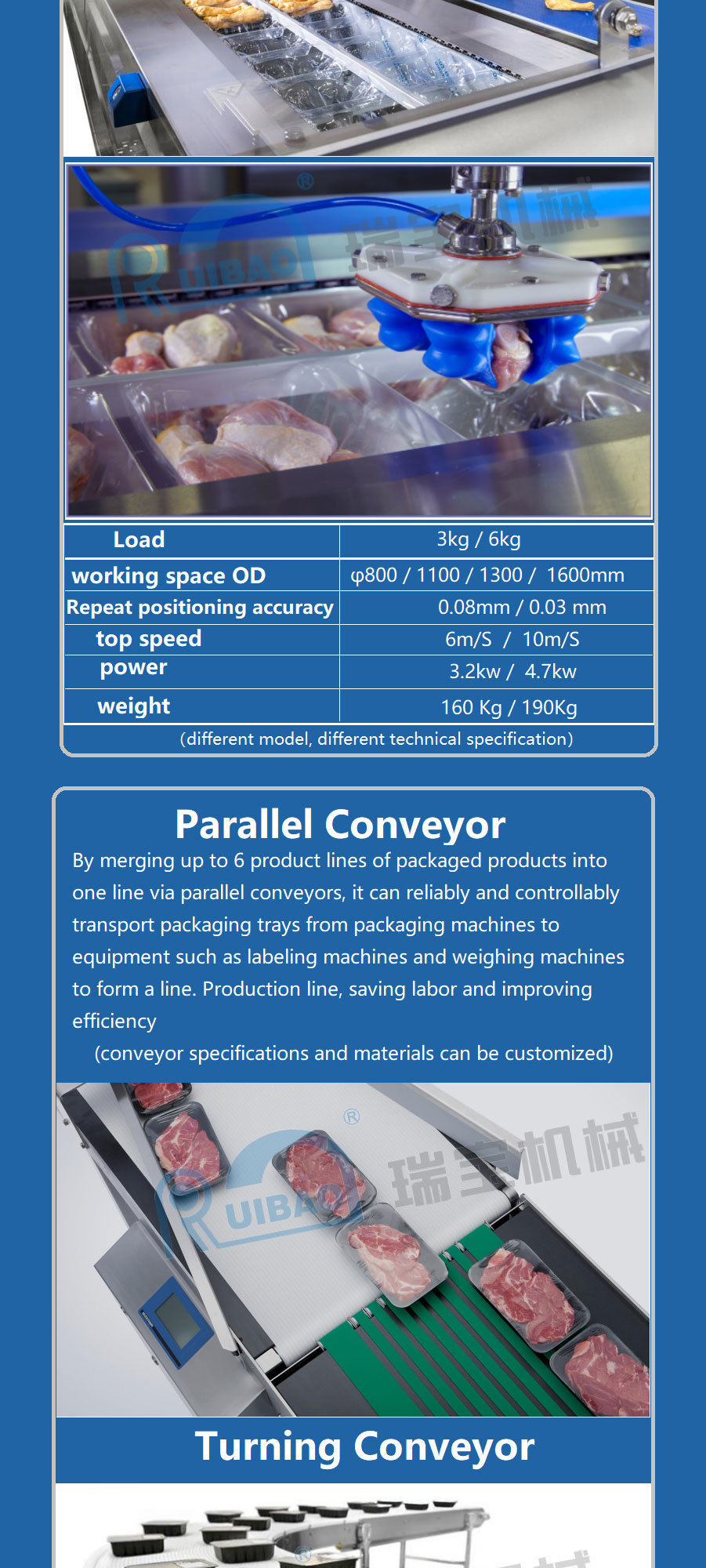

parallel robot grasping system

| Load | 3kg /6kg |

| Working space diameter | φ800/1100/1300/1600mm |

| Repeated positioning accuracy | 0.08mm/0.03 mm |

| Maximum speed | 6m/S /10m/S |

| Power | 3.2kw/4.7kw |

| Weight | 160 Kg/190Kg |

S660 small character inkjet printer

| jet printing dot matrix | Numbers and letters 5x5/5x7/8x10/8x12/12x16/24x24 | ||

| Stored information | Unlimited (limited only by memory card space) | ||

| printing speed | 1510 characters/second (5x 7) | ||

| Printing content | Automatic printing date, time, batch number, serial number, etc. | ||

| Printing distance | The maximum distance from the nozzle to the object is 30mm | ||

| printing material | Can print metal, plastic, glass, wood, pipeline and building surface | ||

| Communication Interface | RS232 interface, USB | ||

| Jet printing ink | Optional black, blue, red and other colors of ink | ||

| Overall dimension | 360x270x500mm | Gross weight of whole machine | 28KG |

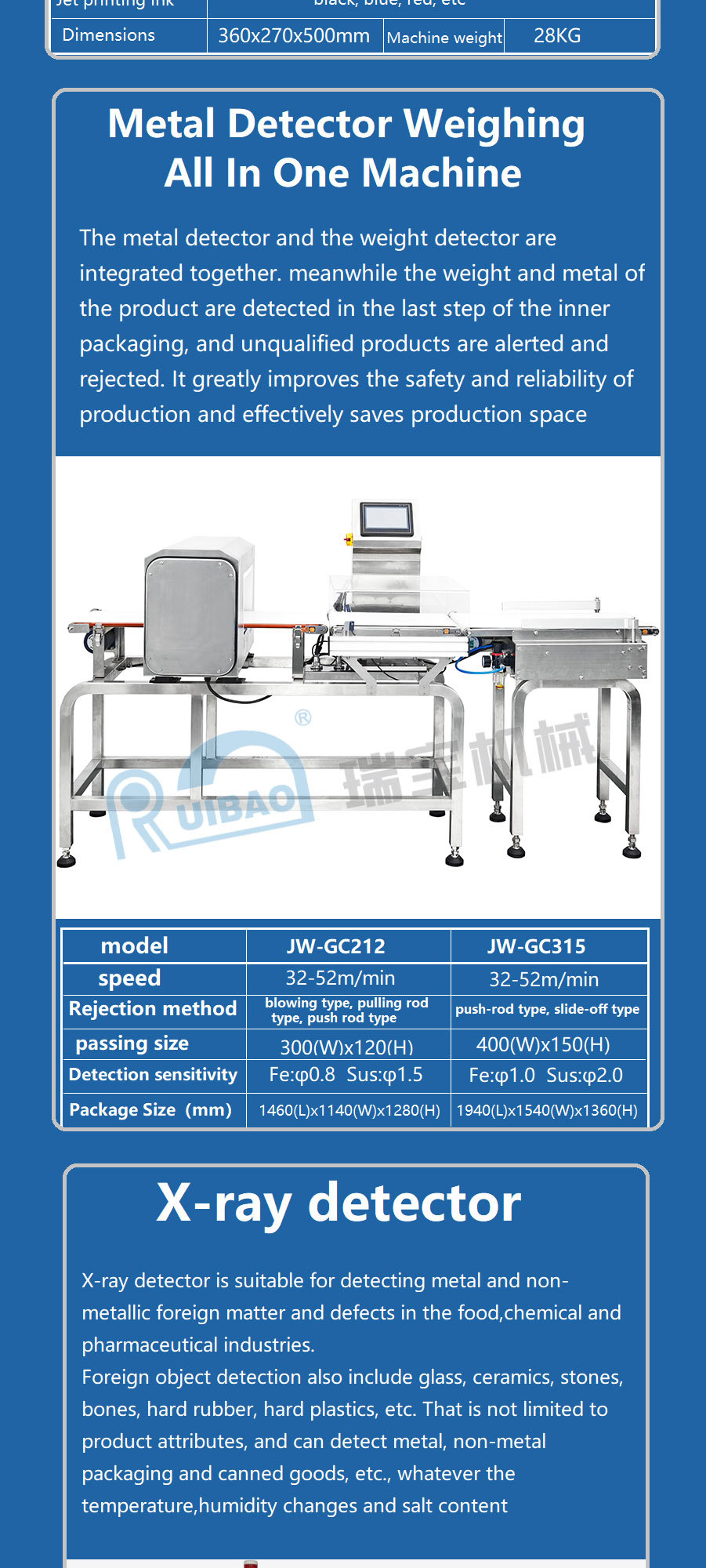

Gold checkweighing machine

| Model | JW-GC212 | JW-GC315 |

| Speed | 32-52m/min | 32-52m/min |

| culling method | Air blowing type/pull rod type/push rod type | Push rod/slide down |

| Through size (mm) | 300(W)x120(H) | 400(W)x150(H) |

| Detection sensitivity (mm) | Fe:φ 0.8 Sus:φ 1.5 | Fe:φ 1.0 Sus:φ 2.0 |

| Packing size (mm) | 1460(L)x1140(W)x1280(H) | 1940(L)x1540(W)x1360(H) |

X-ray foreign body detector

| Model | GJ-XF-2512/2518 | GJ-XF-4015/4023 |

| Sensitivity | Metal Ball 0.3mm Metal Wire 0.2x2mm Glass Ball 2.0mm | |

| Conveyor channel size | W250xH120/180mm | W400 xH150/230mm |

| Conveyor Speed | 20m/minute | |

| Maximum Load | 5kg | 10kg |

| Alarm Method | Conveyor auto Stop (Standard)/Rejection System (Optional) | |

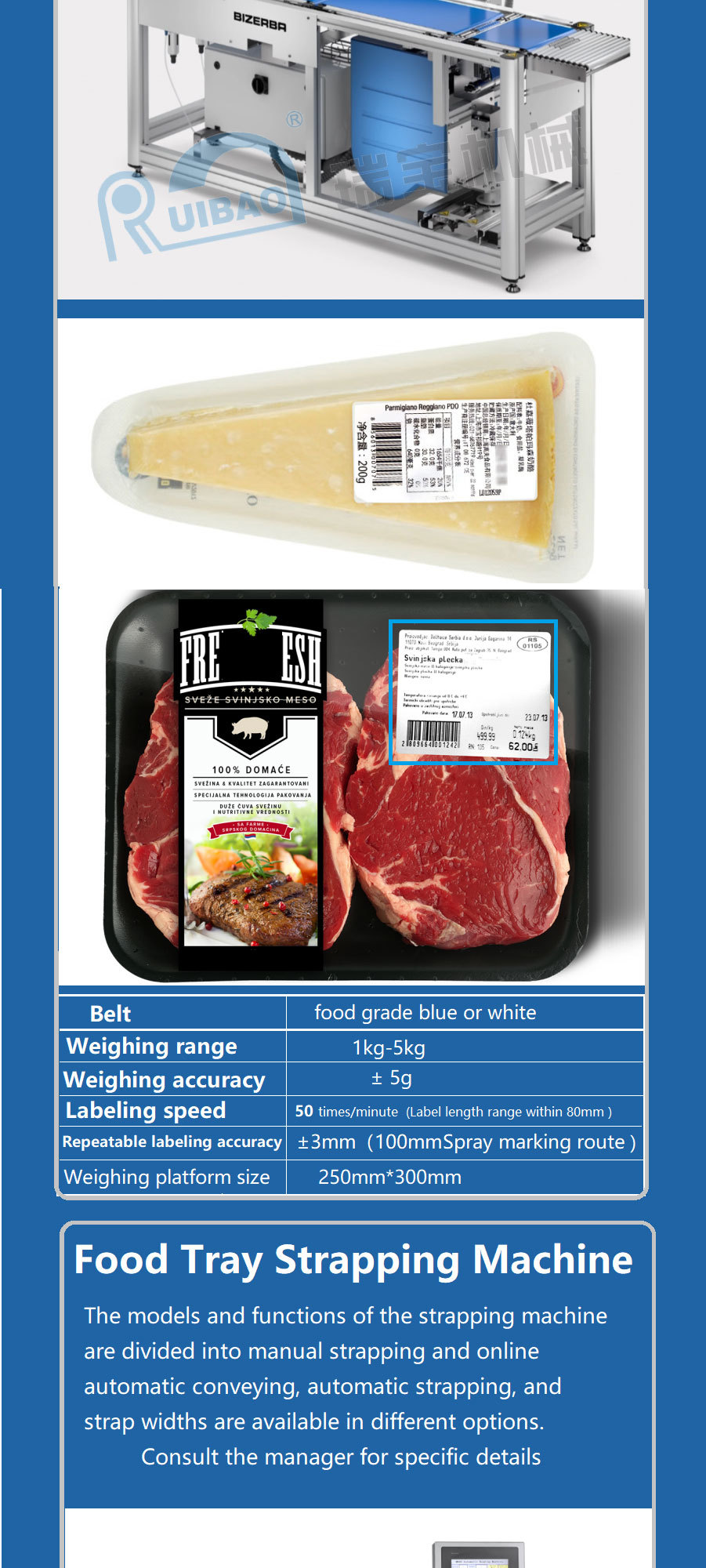

Weighing, printing and labeling all-in-one machine

| Belt | Blue or white food grade |

| Weighing range | 1kg-5kg |

| Weighing accuracy | ±5g |

| Labeling speed | 50 times/min (within the length of the label 80mm) |

| Repeat labeling accuracy | ± 3mm(100mm spray stroke) |

| Scale | 250mm*300mm |

pallet belt machine

| Applicable Consumables Specifications | OPP film tape: thickness: 40-130mic paper tape: weight: 80g/m2 |

| Different models/different bandwidth | 30/40/50/75/100/125/150mm wide band |

| Dimensions in the frame | W370xH200mm |

| Packing speed | 2.0 sec/track |

| Bundling force | 5-40N |

| Applicable package size | Maximum: width 340 x height 195mm/minimum: width 50x height 10mm |

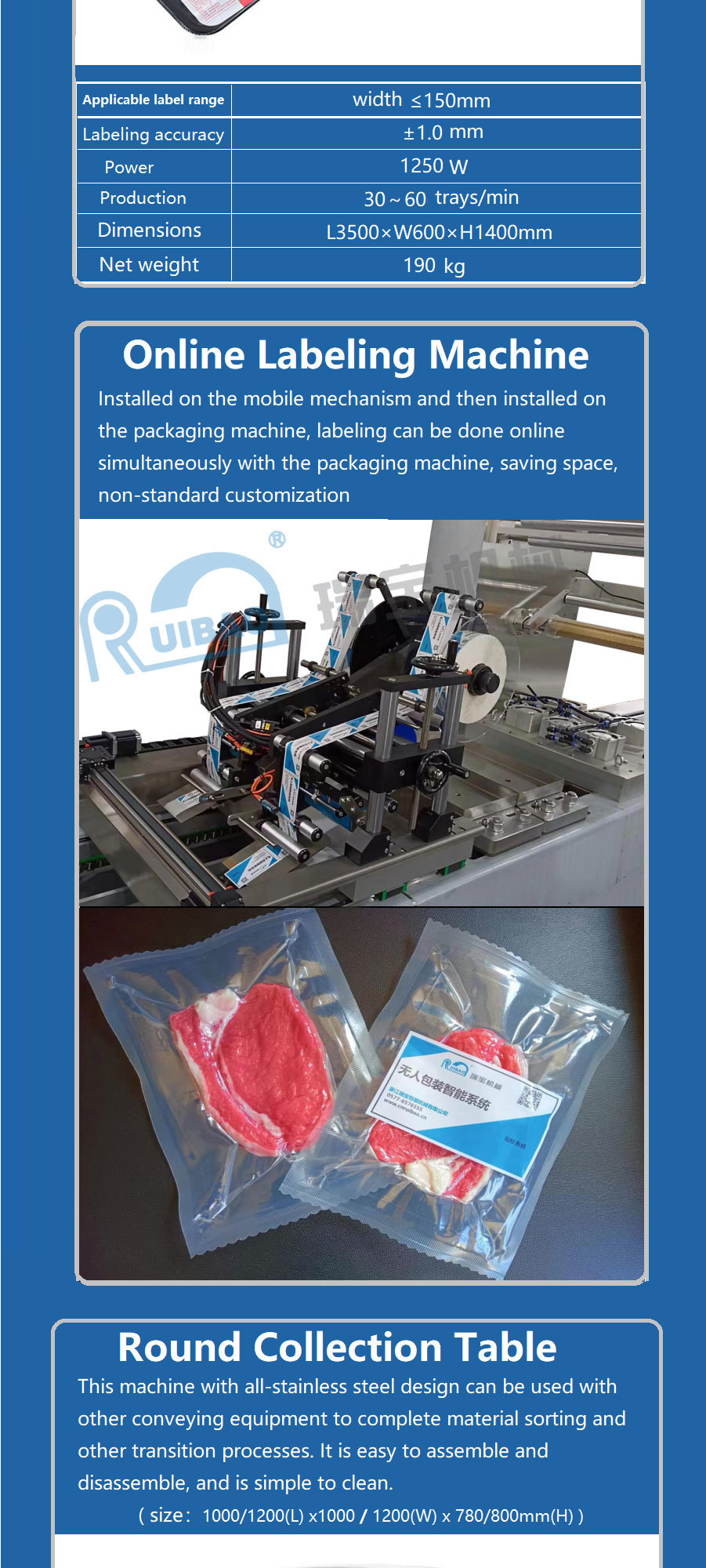

Automatic plane labeling machine

| Applicable label scope | Width ≤ 150mm |

| Labeling accuracy (mm) | ±1.0 |

| Overall power (W) | 1250 |

| Yield | 30~60 (boxes/min) |

| Overall dimension | L3500 × W600×H1400 mm |

| Net weight (kg) | 190 |

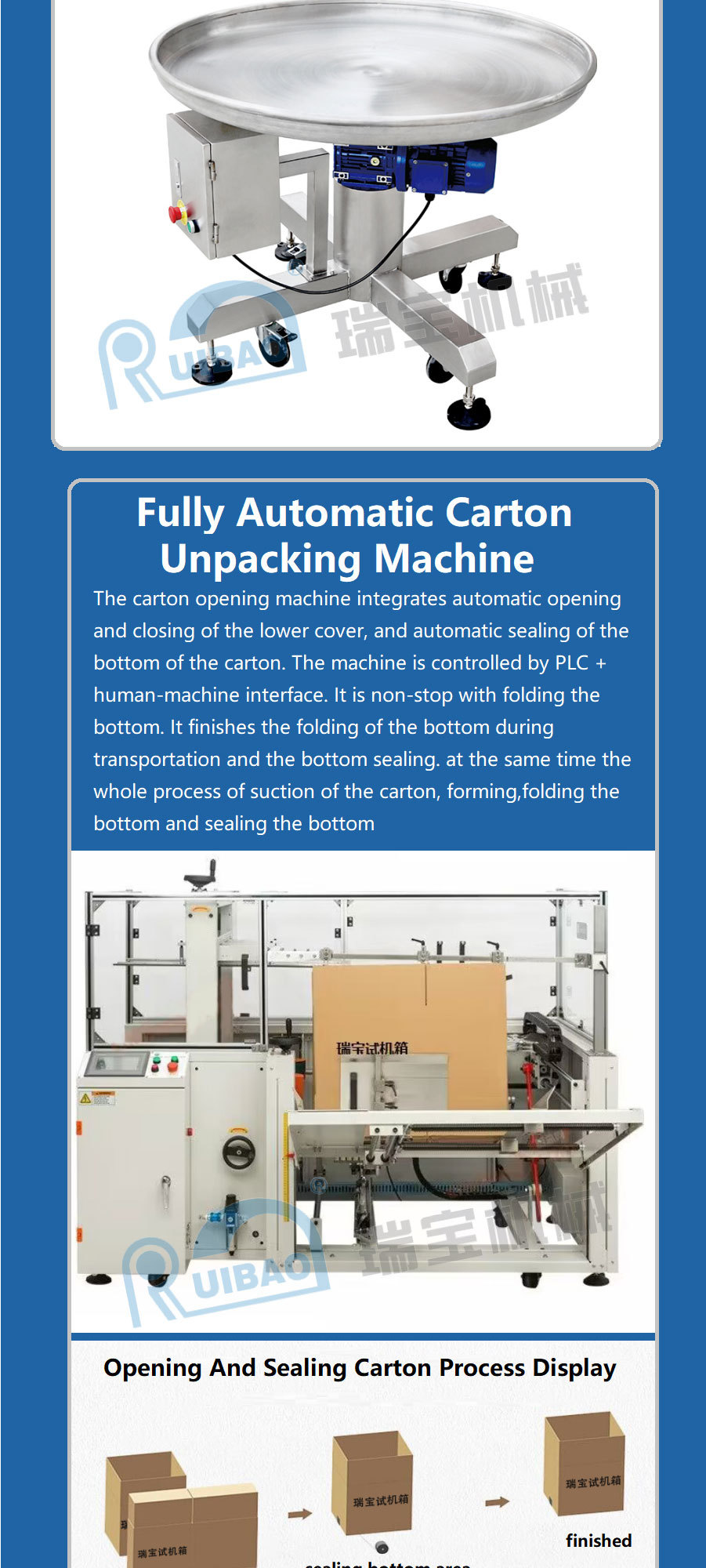

DKX-5070 automatic box unpacking machine

| Unpacking speed | 8-12 pcs/min | ||

| Unpacking length range | L350~700mm | ||

| Open box width range | W150~500mm | ||

| Unpacking height range | H150~500mm | ||

| Exterior dimension | (length X width X height) L2400XW1300XH1665 mm ~ 1750mm | ||

| Work surface | Height 600mm | Power | 240W |

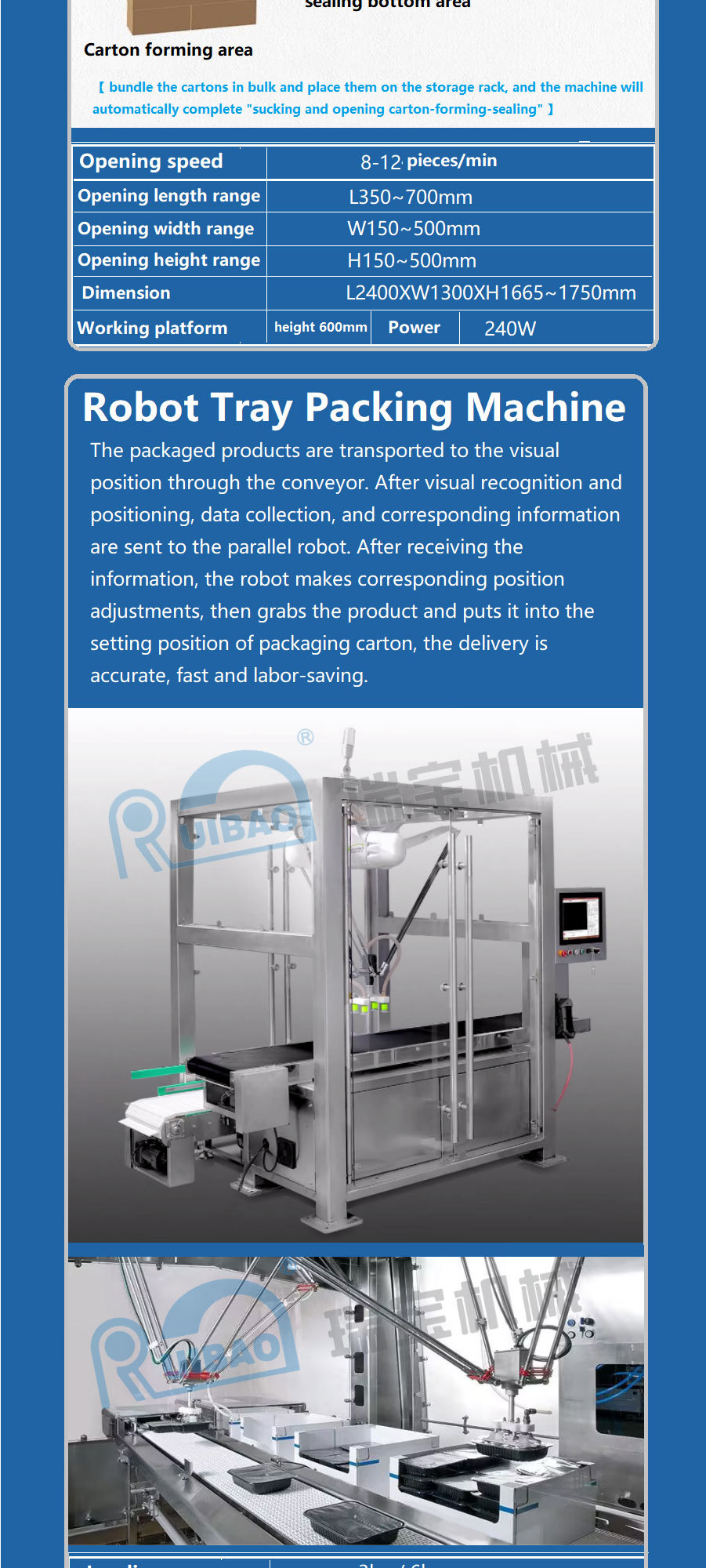

Robot pallet packing machine

| Load | 3kg/6kg |

| Working space diameter | φ800/1100/1300/1600mm |

| Repeated positioning accuracy | 0.08mm/0.03 mm |

| Maximum speed | 6m/S/10m/S |

| Power | 3.2kw/4.7kw |

| Weight | 160Kg/190Kg |

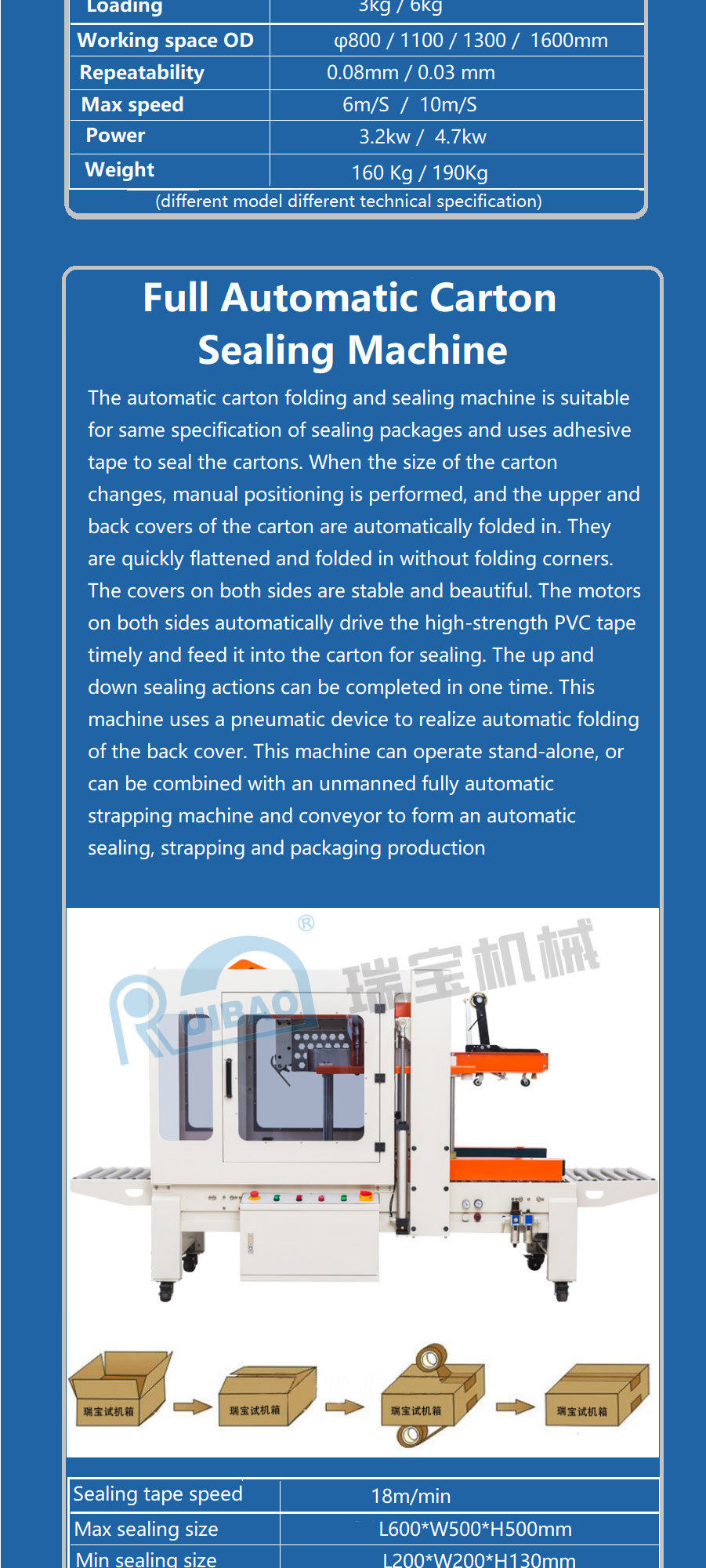

FXZ5050 automatic carton sealing machine

| Sealing belt speed | 18m/min |

| Maximum sealing size | (length X width X height) L600 * W500 * H500mm |

| Minimum packing size | (length X width X height) L200 * W200 * H130mm |

| Work surface | Height L600-720mm |

| Transmission mode | Conveyor belt drive on both sides |

| Machine shape | L2840*W1010*H(1600-1700)mm |

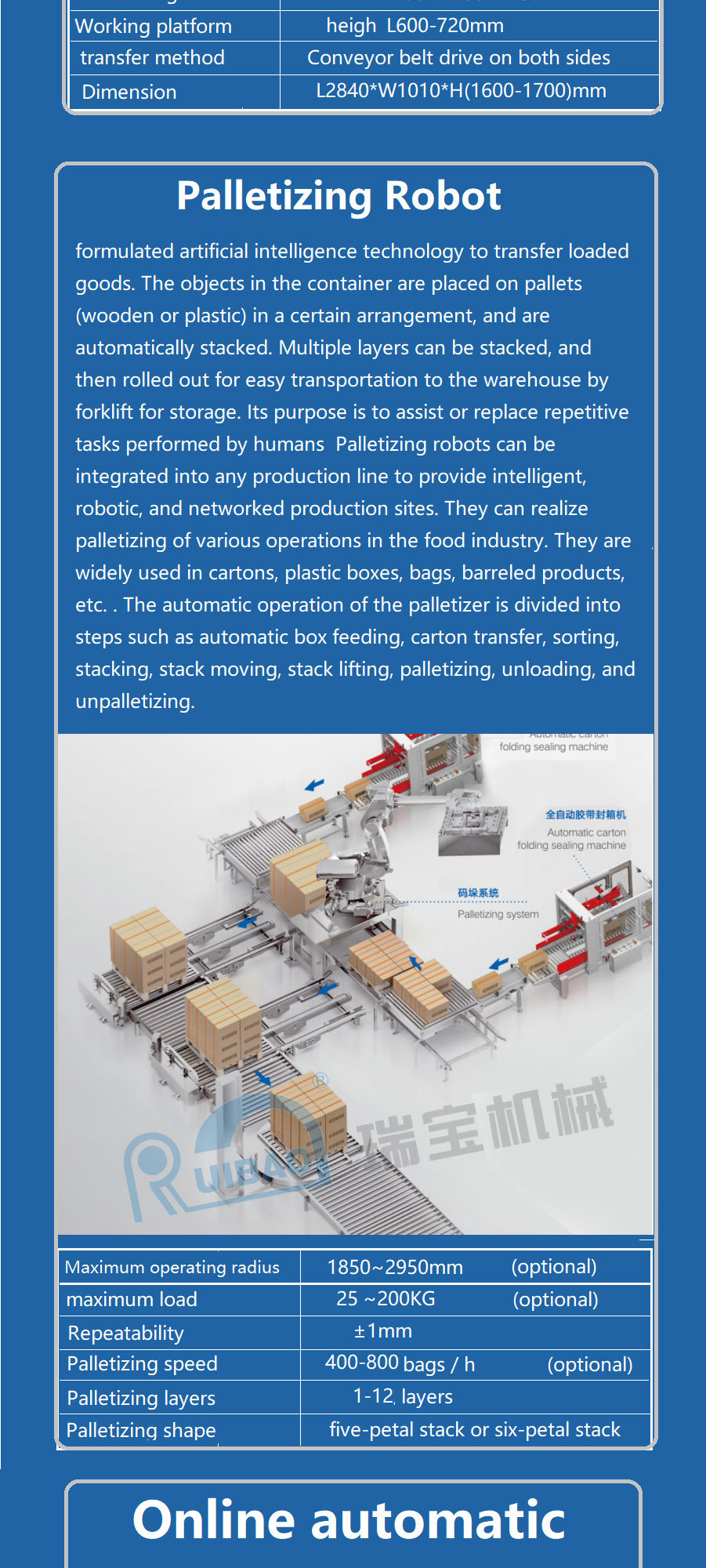

Palletizing robot

| Maximum operating radius | 1850~2950mm (optional) | |

| Maximum load | 25~200KG (optional) | |

| Repeated positioning accuracy | ±1mm | |

| palletizing speed | 400-800 packs/hour (optional) | |

| Number of palletizing layers | Layers 1-12 | |

| Palletizing shape | Five-flower stack or six-line stack | |

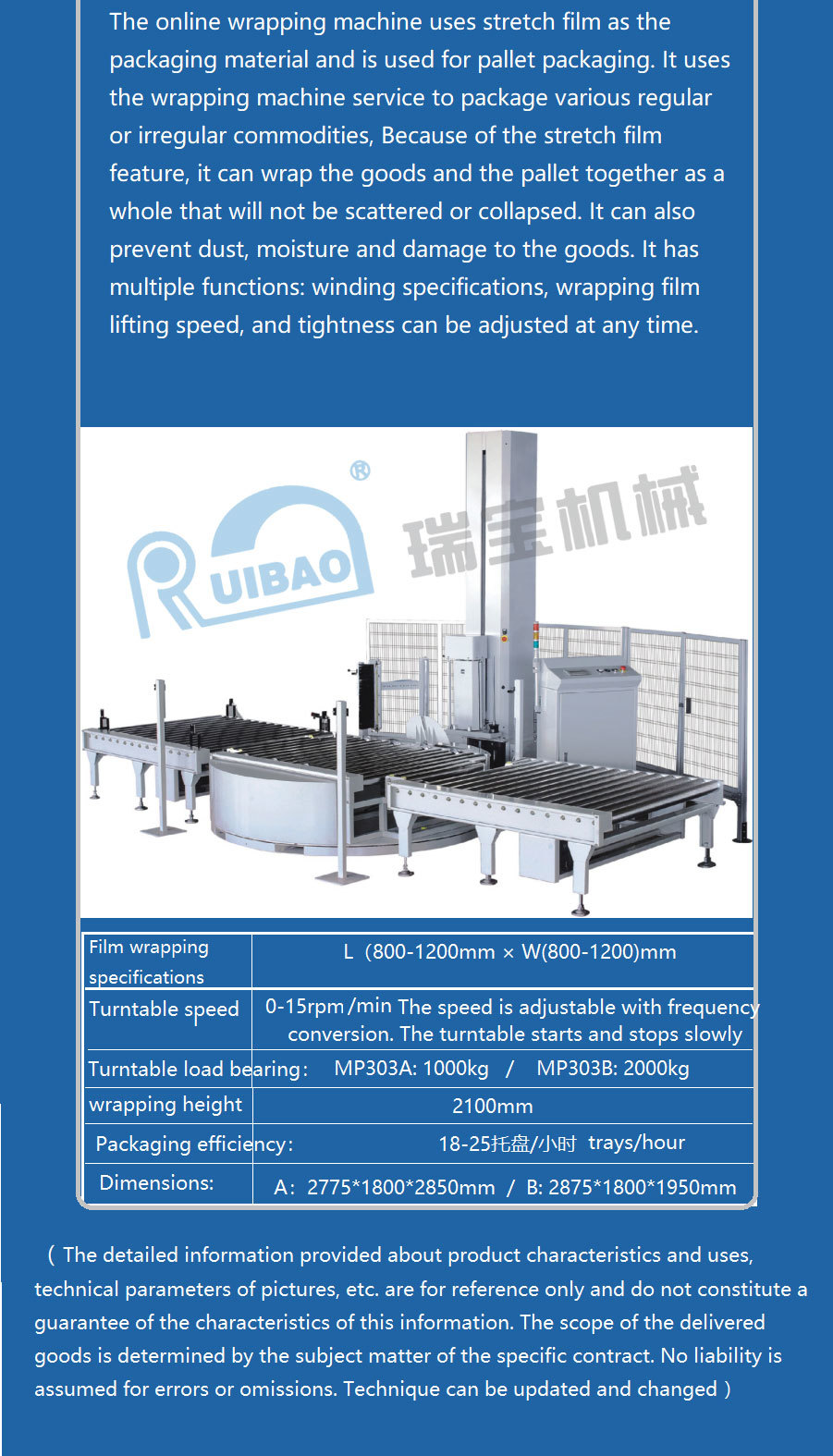

On-line automatic film winding machine

| Wound film specifications | L(800-1200mm × W(800-1200)mm |

| Turret speed | 0-15rpm/min, adjustable speed frequency conversion, slow start and stop of the turntable |

| Load bearing of turntable: | MP303A:1000kg/MP303B:2000kg |

| Film wrapping height | 2100mm |

| Packing efficiency | 18-25 trays/hour |

| Overall dimension | A:2775*1800*2850mm/B:2875*1800*1950mm |

Leave us a message

SAF Coolest v1.3.1.1 设置面板 HMZSX-ZXJW-OQAQE-AAA

无数据提示

Sorry, the current column is being updated, stay tuned!

You can look at other columns or go backHome Page