Product Classification

Tel/Wechat/Whatsapp

Model:

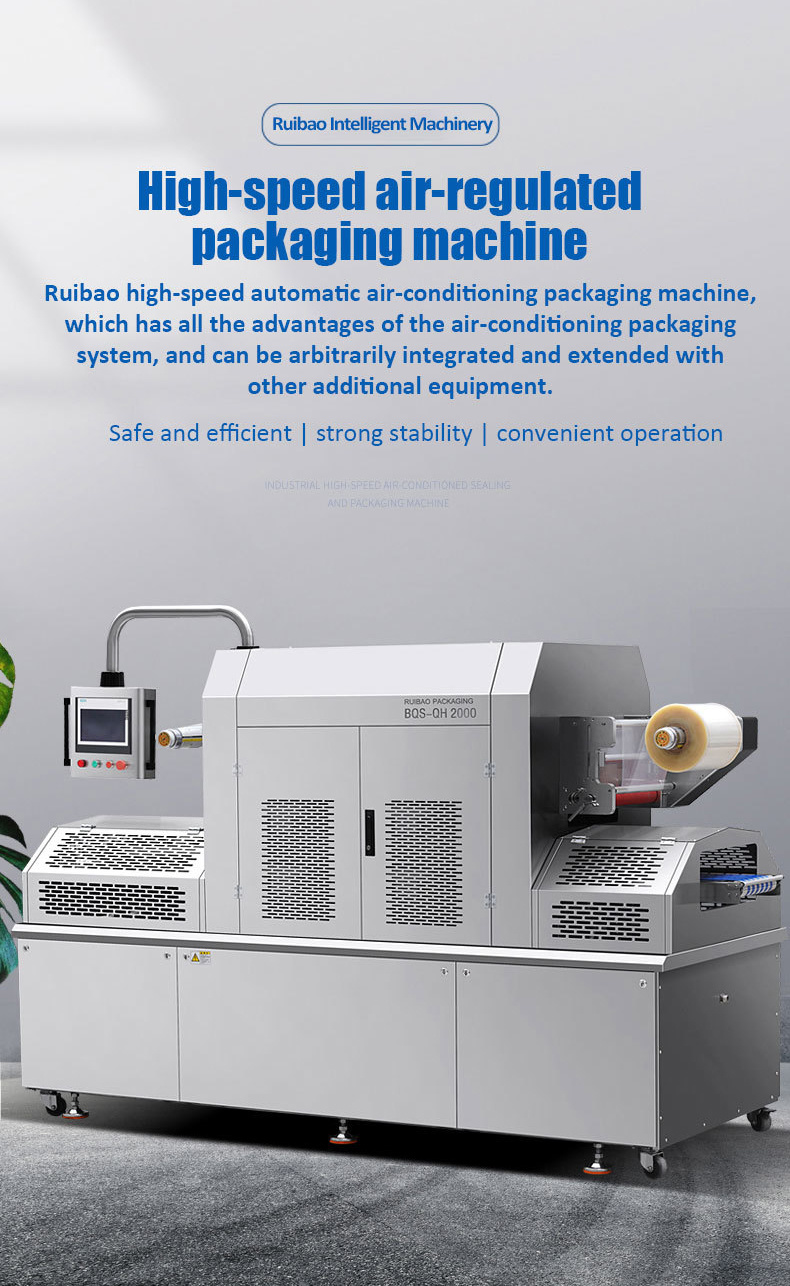

BQS-QH-2000 (support customization)

MOQ: 1

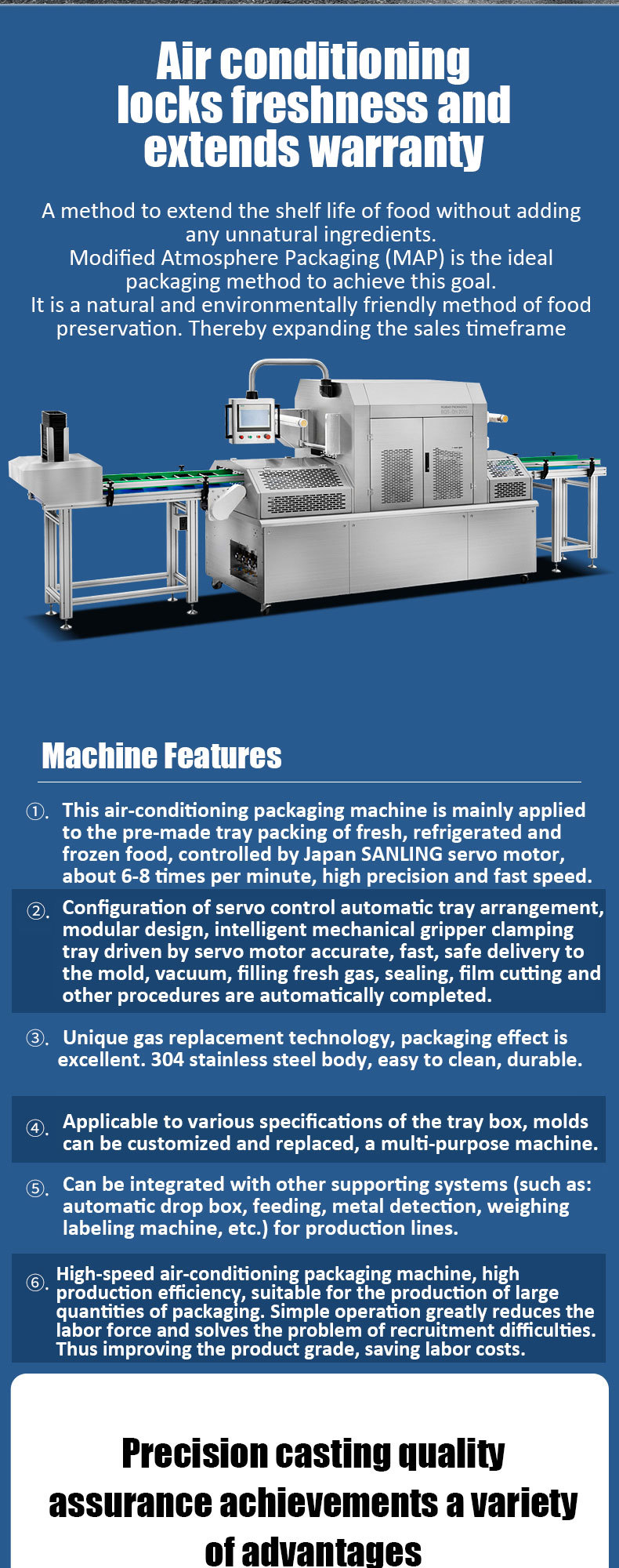

Features: continuous box feeding, sealing, can be connected to various production lines, high speed and high efficiency

Applicable products: fresh meat, fruits and vegetables, cooked fast food and other sealed packaging modified atmosphere packaging

Keywords:

(High-speed) modified atmosphere packaging machine

Category:

Prefabricated box packaging machine

Modified atmosphere packaging machine

Product Center

The thermoforming vacuum packaging machine is an advanced packaging equipment which is widely used in food, pharmaceutical, chemical and other industries. It extends the shelf life of food and preserves its freshness by adsorving the Plastic Sheet on the mold after being soft by heating and using vacuum air extraction to extract air inside the packing bag, which leads to the formation of a vacuum packing bag.

EMAIL:

Tel/Wechat/WhatsApp:

Packaging Materials:

Prefabricated box

Capacity:

High

Packaging Technology:

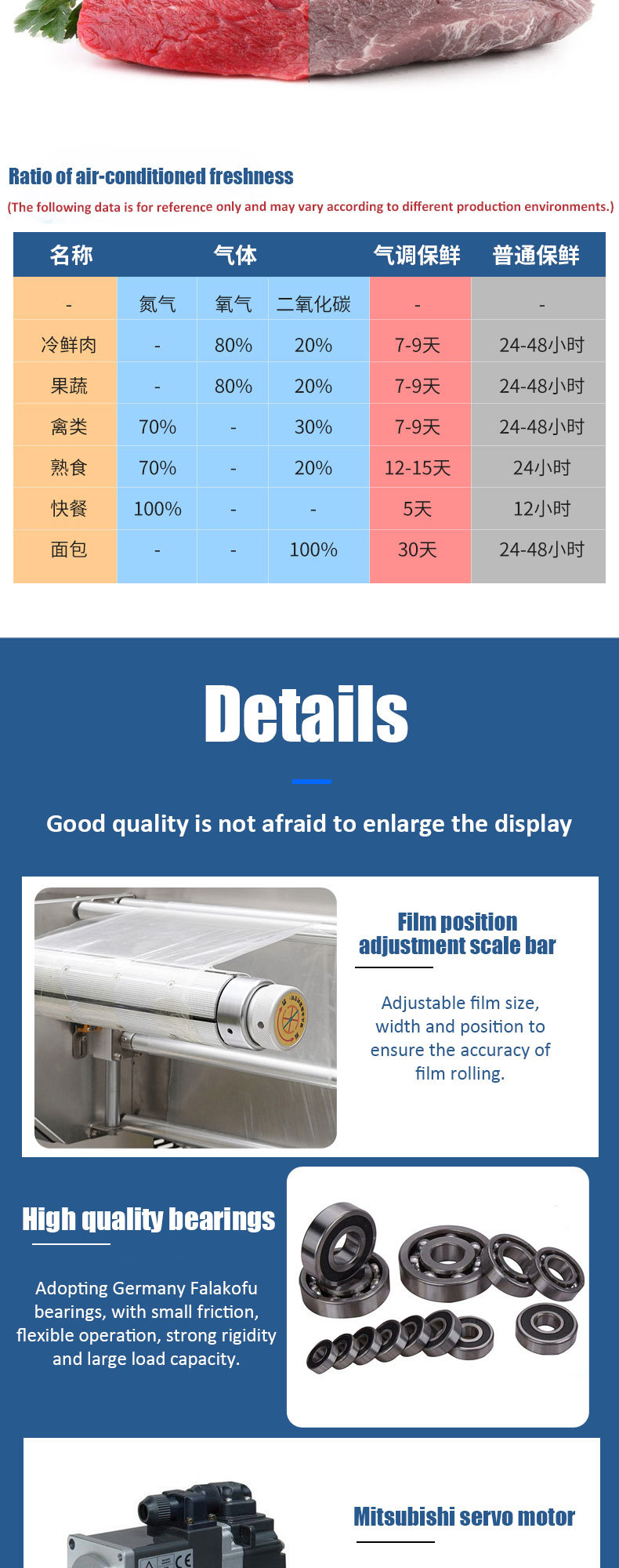

Modified atmosphere,Balanced atmosphere,Natural seal

The thermoforming vacuum packaging machine is an advanced packaging equipment which is widely used in food, pharmaceutical, chemical and other industries. It extends the shelf life of food and preserves its freshness by adsorving the Plastic Sheet on the mold after being soft by heating and using vacuum air extraction to extract air inside the packing bag, which leads to the formation of a vacuum packing bag.

The working principle of the thermoforming vacuum packaging machine is to form the bottom of the packaging bag by heating the plastic sheet so that it is limed and adsorbed on the mold. Then, after placing the food inside the packing bag, the air inside the packing bag is removed by a vacuum pump, and the final cap forms a vacuum packing bag. This can effectively prevent moisture and food deterioration, prolong the shelf life of food, and maintain the freshness and taste of food.

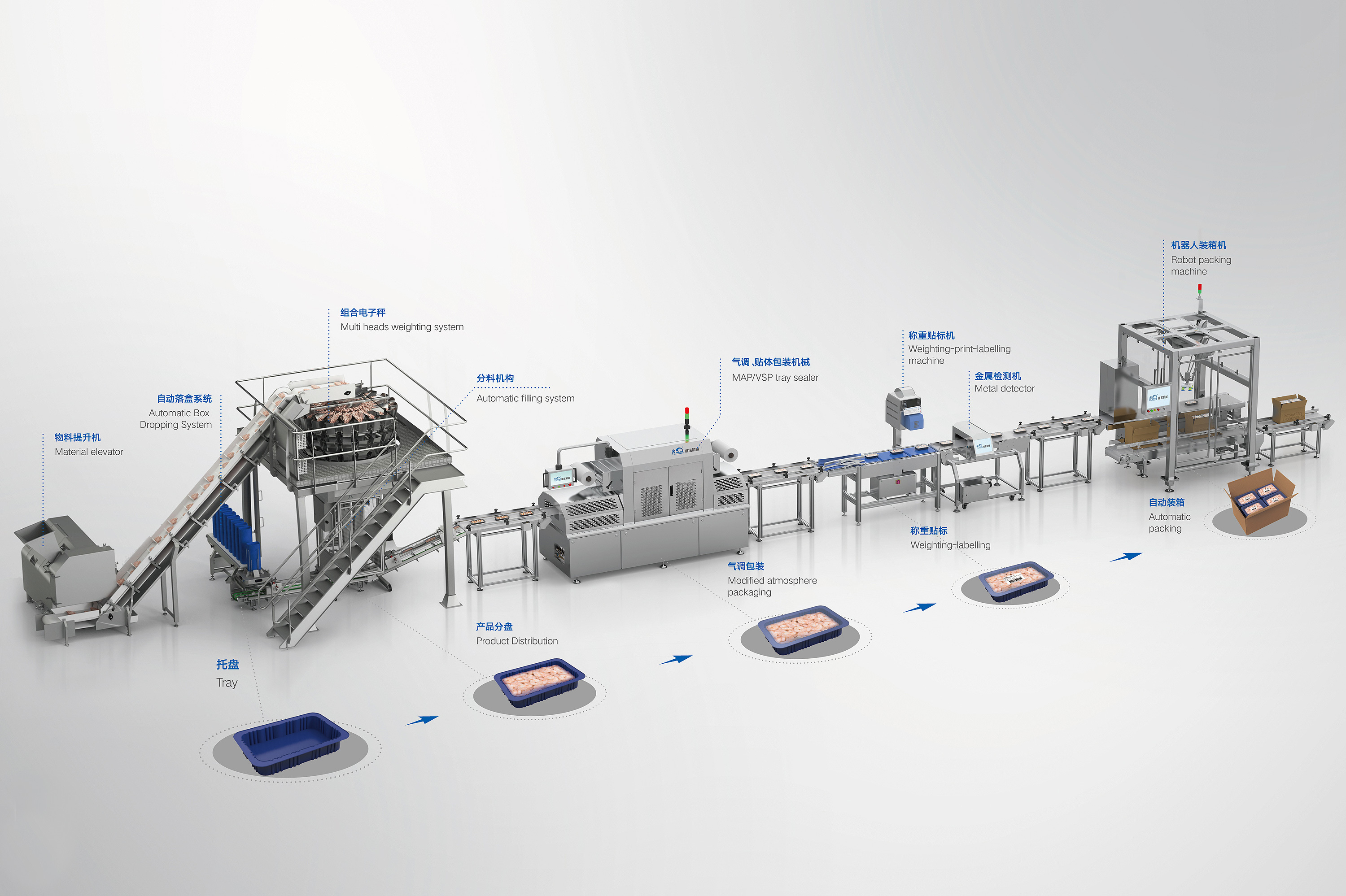

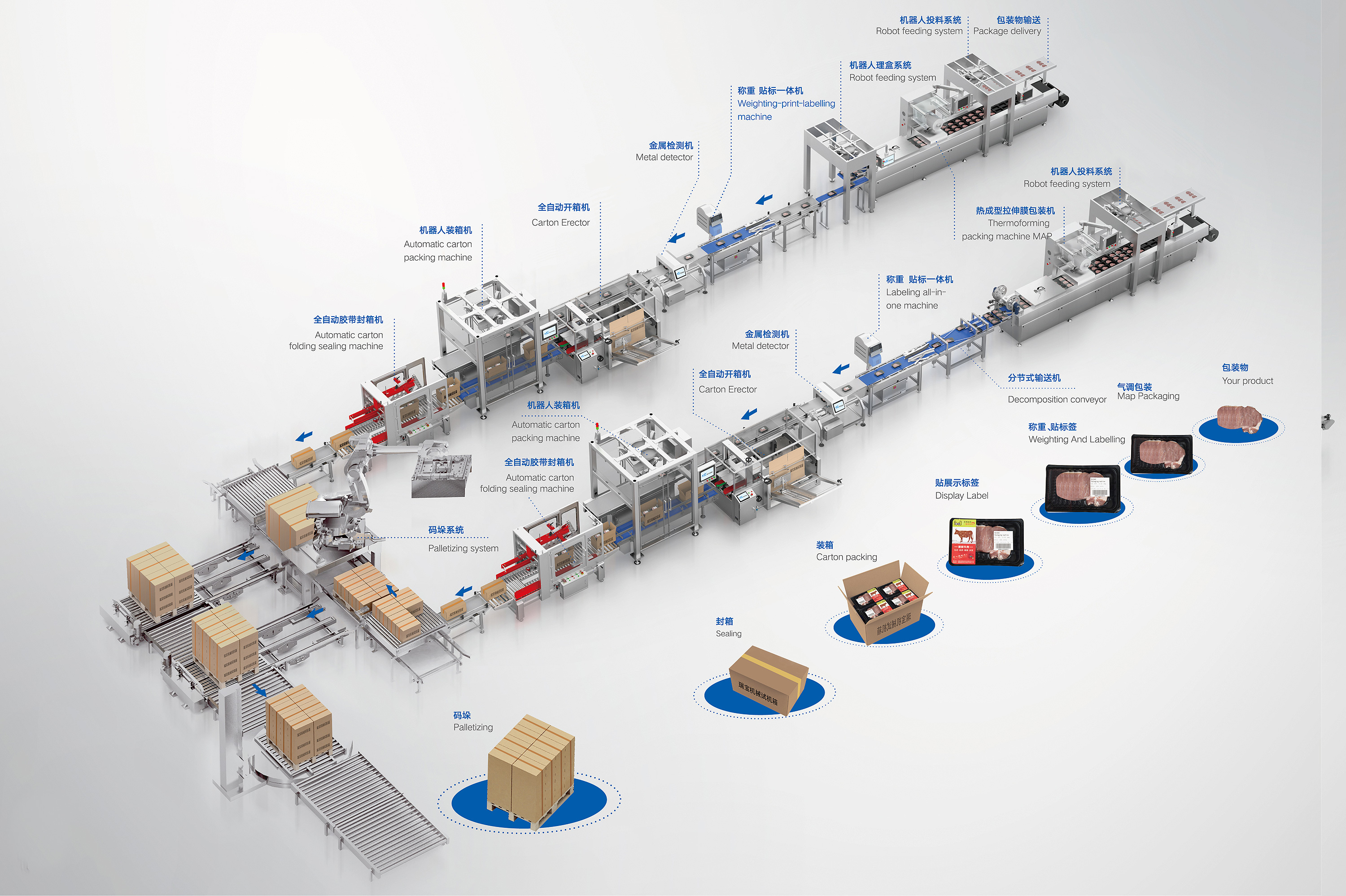

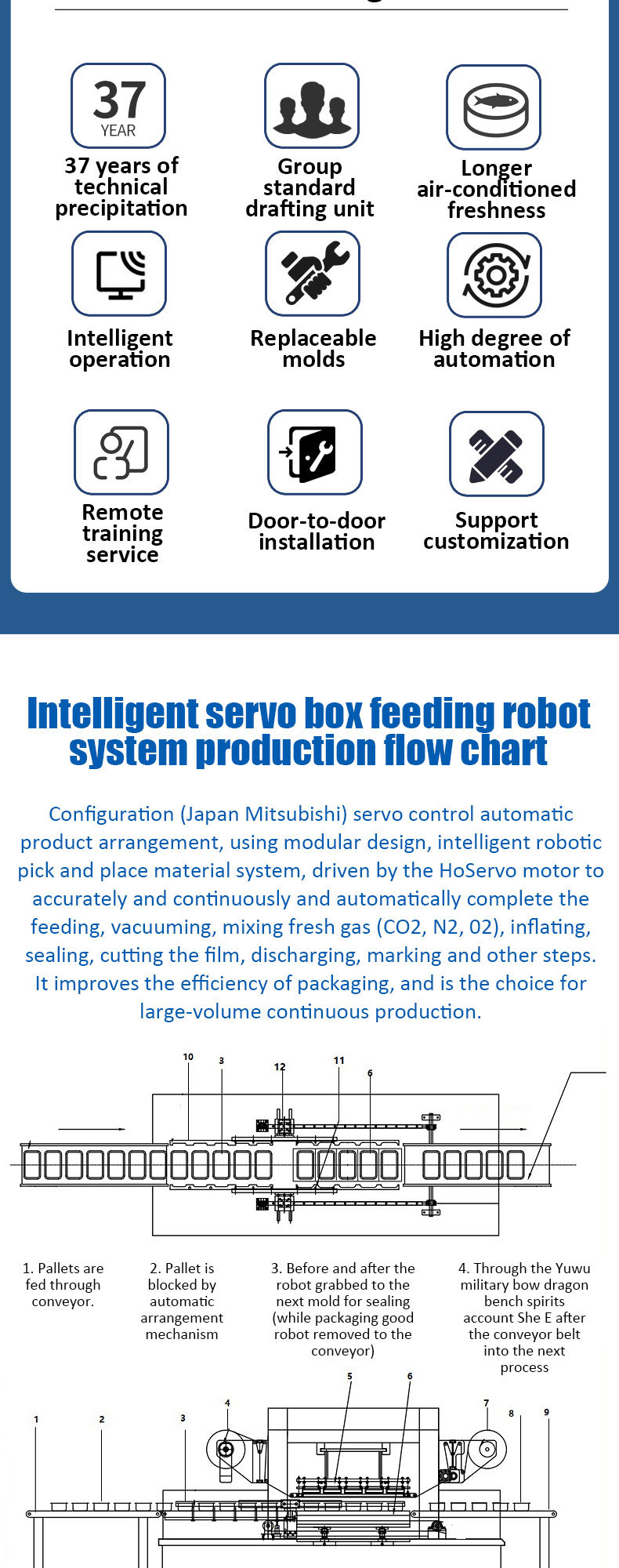

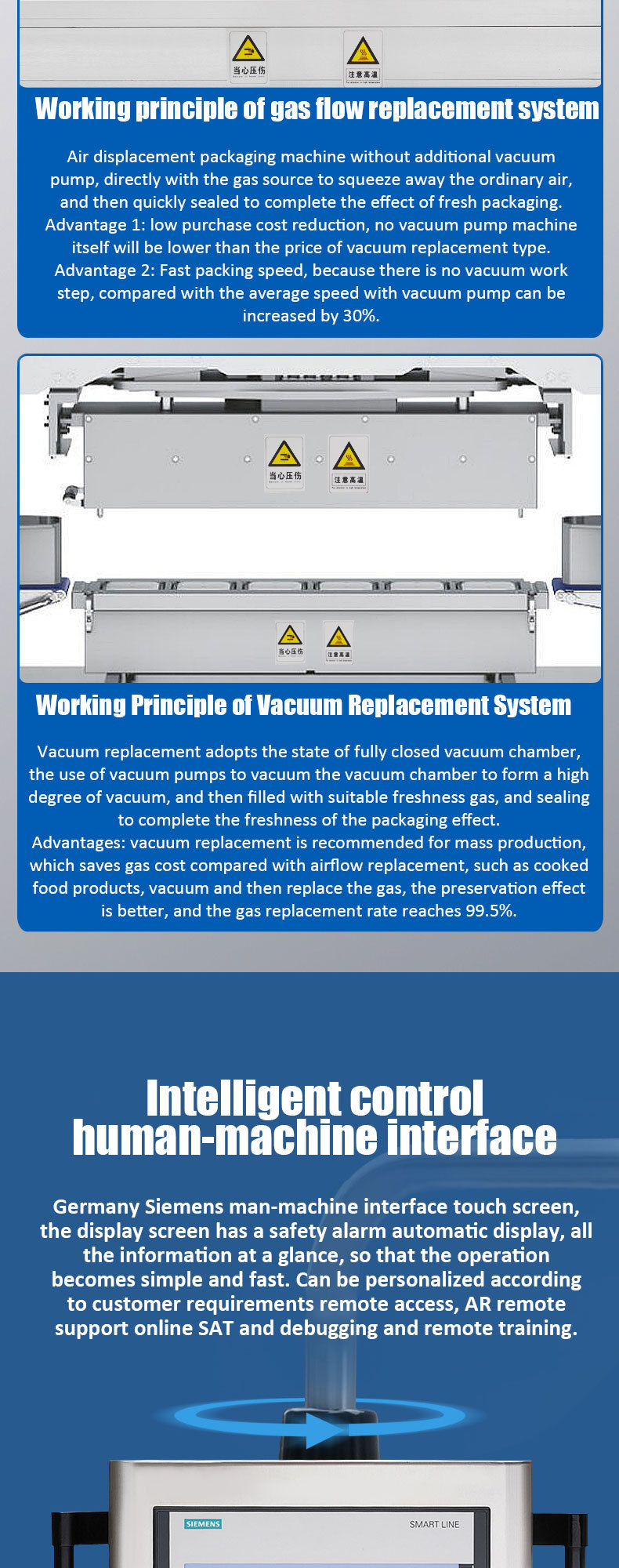

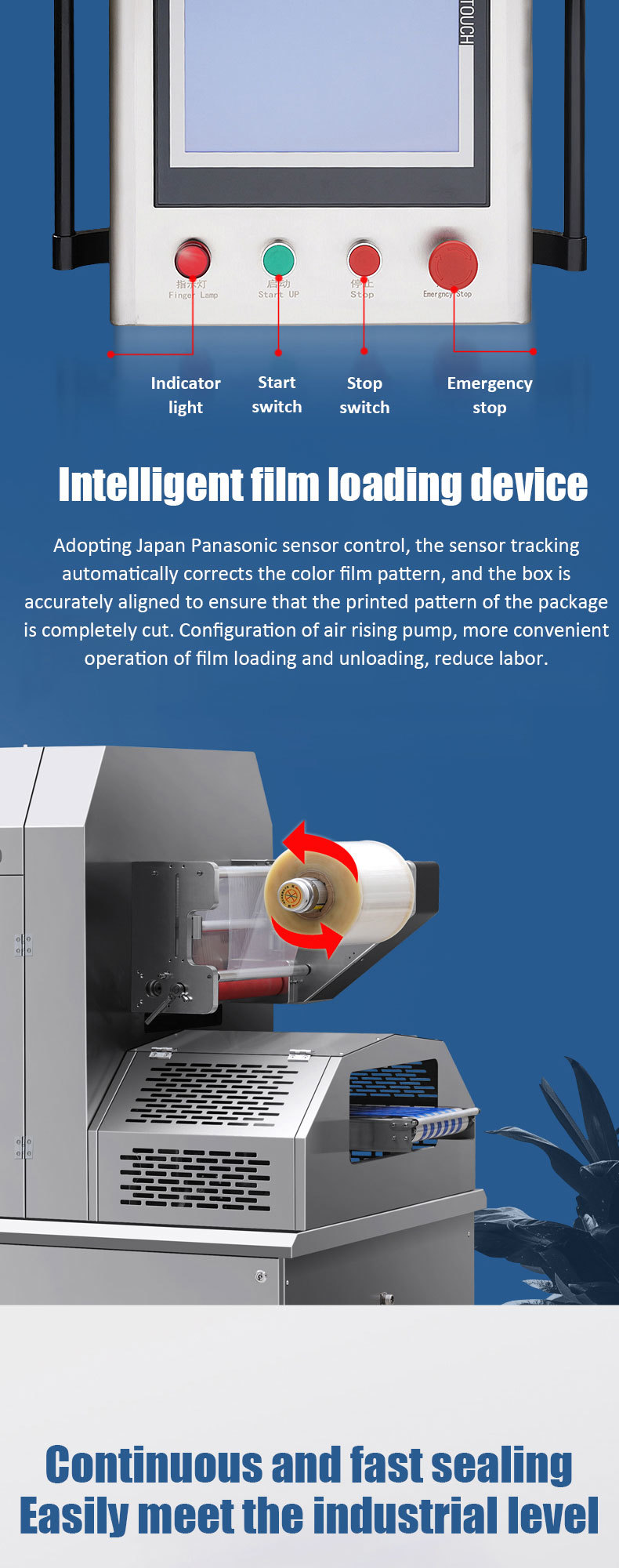

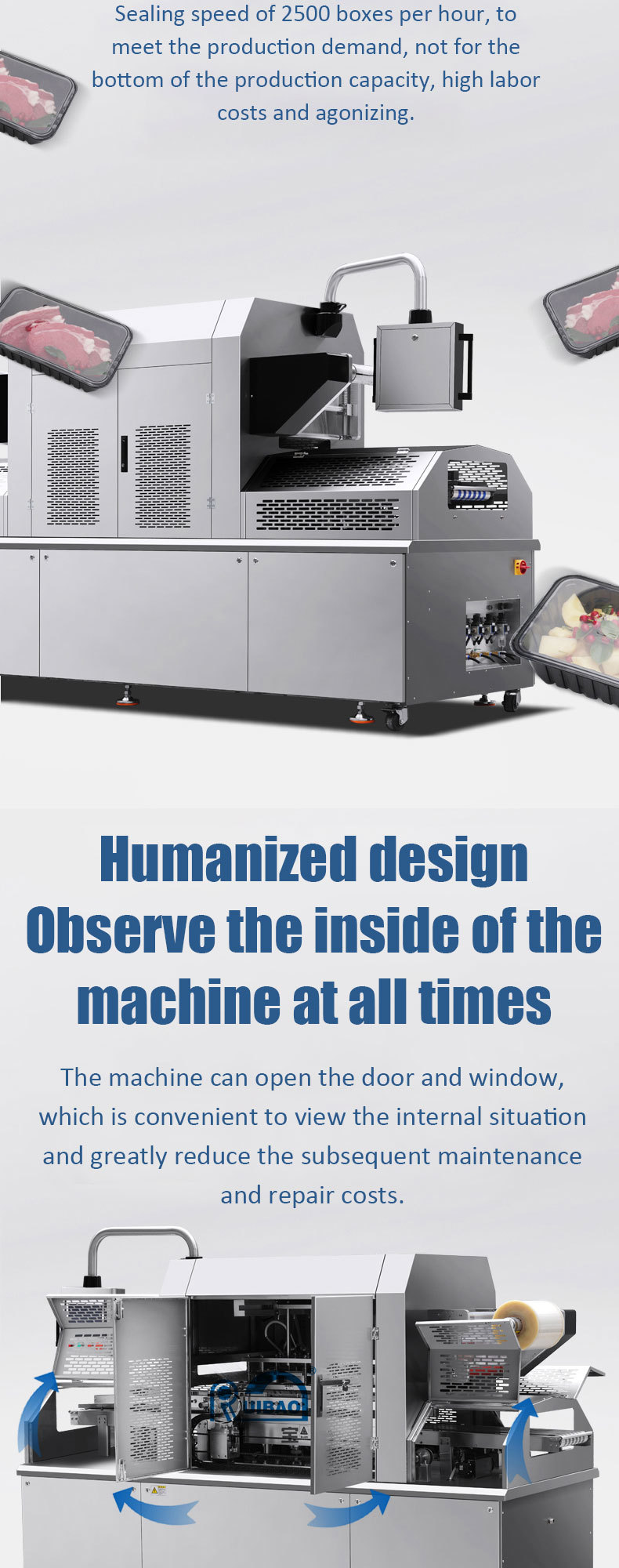

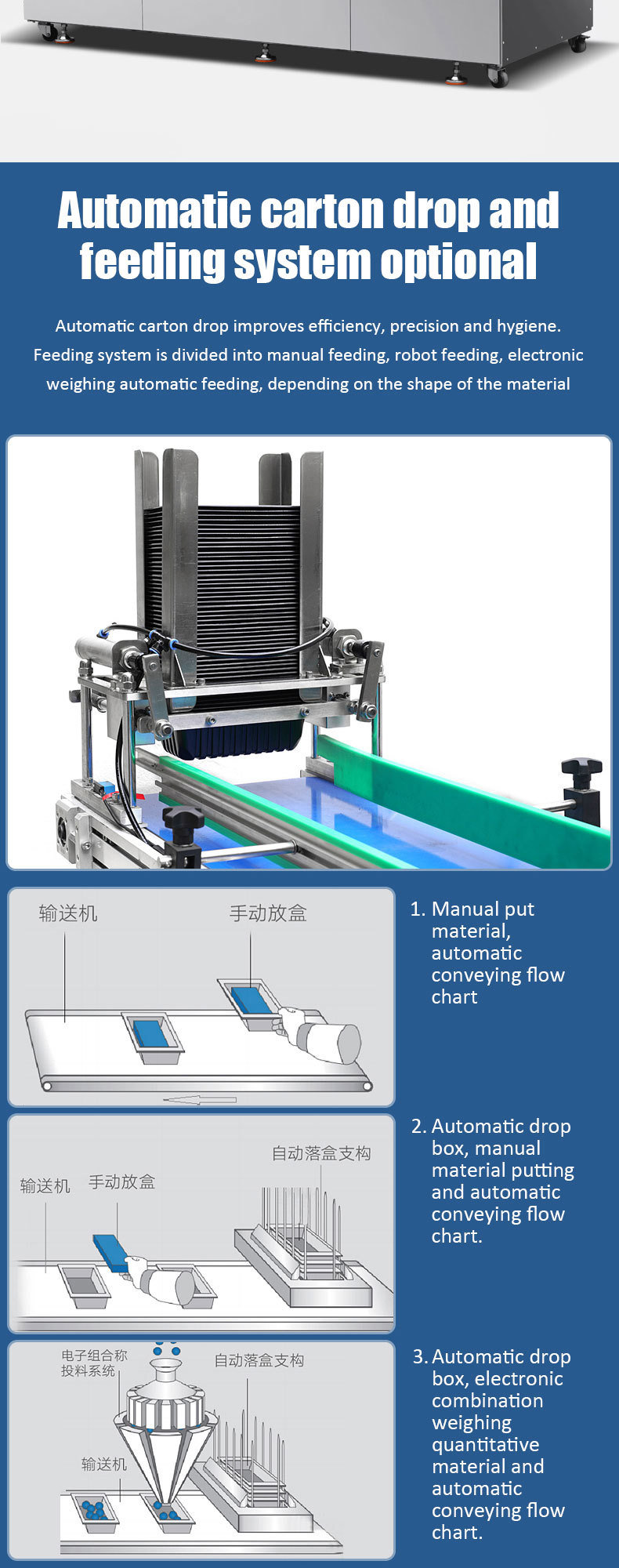

● (high-speed) modified atmosphere packaging machineThe servo-controlled conveyor is configured to automatically arrange, position and transport the pallets. The pallets clamped by the intelligent mechanical gripper are accurately, quickly and safely transported to the mold by the servo motor. The programs such as vacuumizing, filling fresh-keeping gas, sealing, film cutting and finished product output are automatically completed. Greatly shorten the cycle packaging time. Improve packaging speed, save labor and purchase cost. The whole machine has high degree of automation, simple operation and low defective rate.

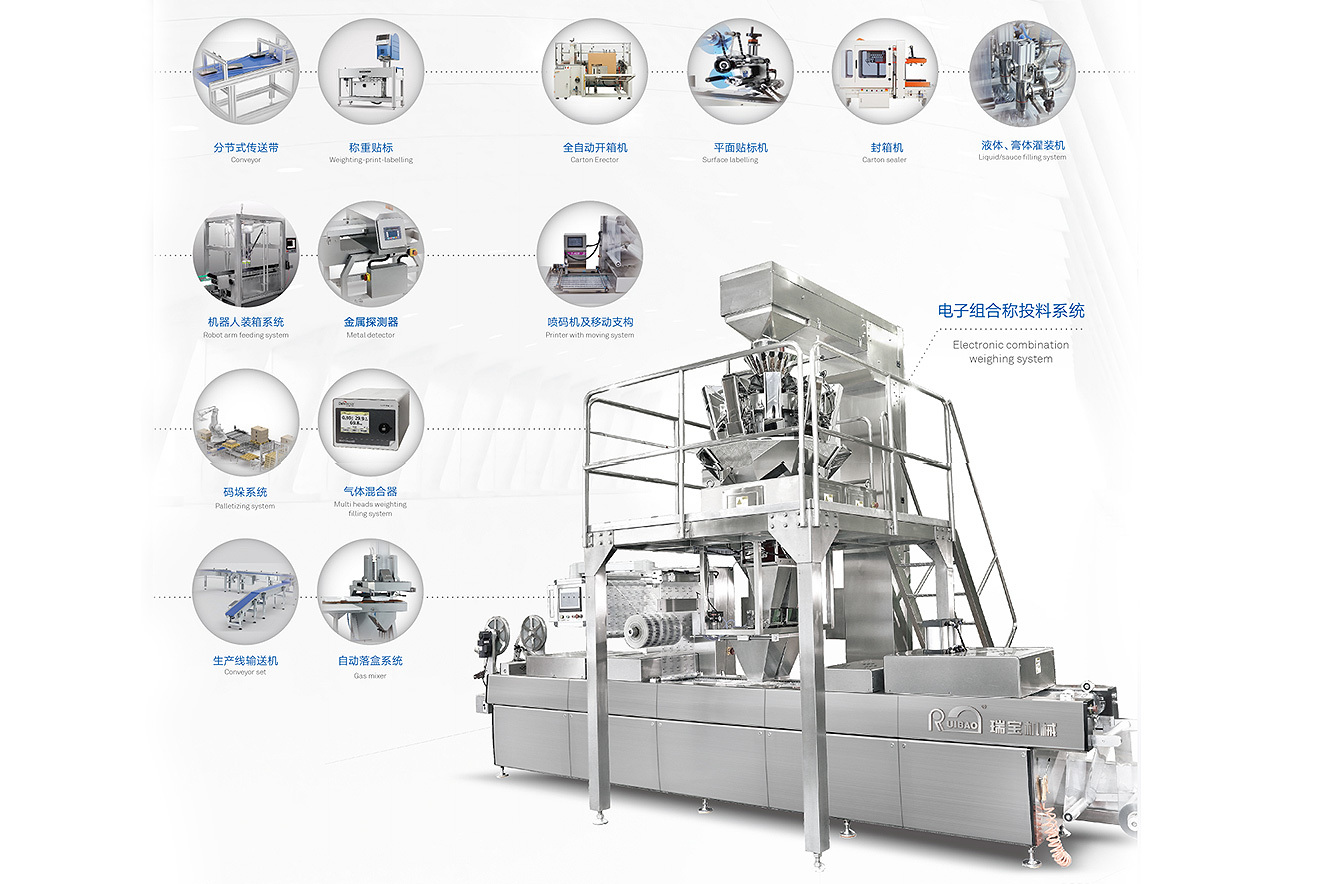

● At the same time, the packaging machine can be equipped with various third-party auxiliary equipment such as; Pallet separator, automatic filling equipment, combination weighing, conveyor belt, weighing/labeling, metal detection, manipulator packing, sealing, palletizing, etc. Automated packaging can greatly save manpower.

● The use of replaceable mold design, can make a device for a variety of specifications tray packaging.

Scope of use

All kinds of cold fresh meat, cooked meat products, seafood, fruits and vegetables, baked goods, agricultural products, fast food and non food applications. So as to extend the color of the product, maintain the taste and shape, and improve the shelf life.

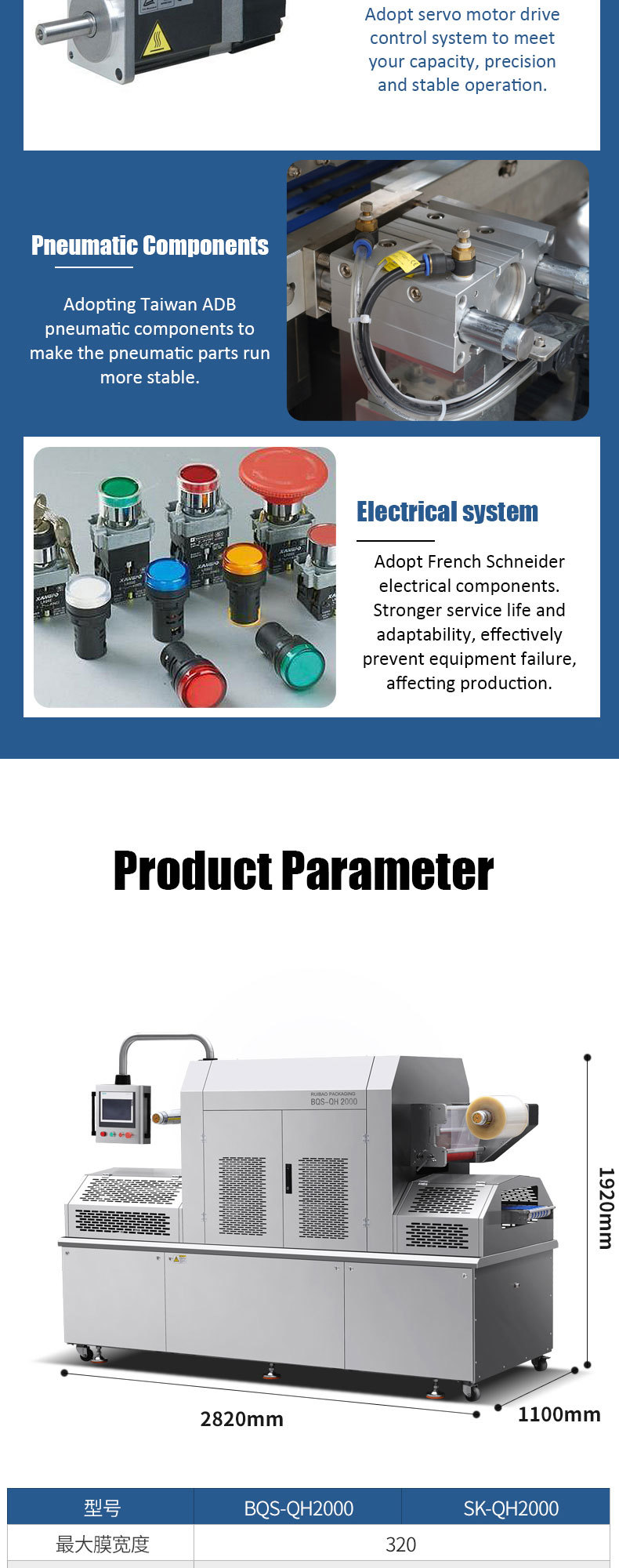

| Model | BQS-QH2000 | SK-QH2000 |

| Maximum film width | 320 | |

| Maximum membrane diameter | 300 | |

| Voltage Power | 6 ~ 10kw380v(110v/220v)50/60Hz (optional) | |

| Air pressure | 0.6~0.8 | |

| Capacity (cycles/min) | ★★★★★ | |

| Gas replacement rate (%) | ≤1% | |

| residual oxygen rate | ≤0.5% | ≤0.5% |

| Weight | 1200kg | 1350kg |

| Overall dimension | 2820*1100*1920mm | 2820*1100*1920mm |

| Gas environment | modified atmosphere map | Fit skin |

| Prefabricated box shape |  |

|

| Prefabricated box material | Hard box, aluminum box, carton | |

Leave us a message

SAF Coolest v1.3.1.1 设置面板 HMZSX-ZXJW-OQAQE-AAA

无数据提示

Sorry, the current column is being updated, stay tuned!

You can look at other columns or go backHome Page