Product Classification

Tel/Wechat/Whatsapp

Model:

DLZ-320/420/520PM series (support customization)

Applicable products: snack food, fresh meat, cooked food taste, fast food, etc

Keywords:

Snack FoodAutomatic thermoforming modified atmosphere packaging machine

Category:

Product Center

Thermoforming packaging machine

Thermoformingmodified atmospherePackaging Machine

The thermoforming vacuum packaging machine is an advanced packaging equipment which is widely used in food, pharmaceutical, chemical and other industries. It extends the shelf life of food and preserves its freshness by adsorving the Plastic Sheet on the mold after being soft by heating and using vacuum air extraction to extract air inside the packing bag, which leads to the formation of a vacuum packing bag.

EMAIL:

Tel/Wechat/WhatsApp:

Packaging Materials:

Roll film

Capacity:

High

Packaging Technology:

Modified atmosphere,Natural seal

The thermoforming vacuum packaging machine is an advanced packaging equipment which is widely used in food, pharmaceutical, chemical and other industries. It extends the shelf life of food and preserves its freshness by adsorving the Plastic Sheet on the mold after being soft by heating and using vacuum air extraction to extract air inside the packing bag, which leads to the formation of a vacuum packing bag.

The working principle of the thermoforming vacuum packaging machine is to form the bottom of the packaging bag by heating the plastic sheet so that it is limed and adsorbed on the mold. Then, after placing the food inside the packing bag, the air inside the packing bag is removed by a vacuum pump, and the final cap forms a vacuum packing bag. This can effectively prevent moisture and food deterioration, prolong the shelf life of food, and maintain the freshness and taste of food.

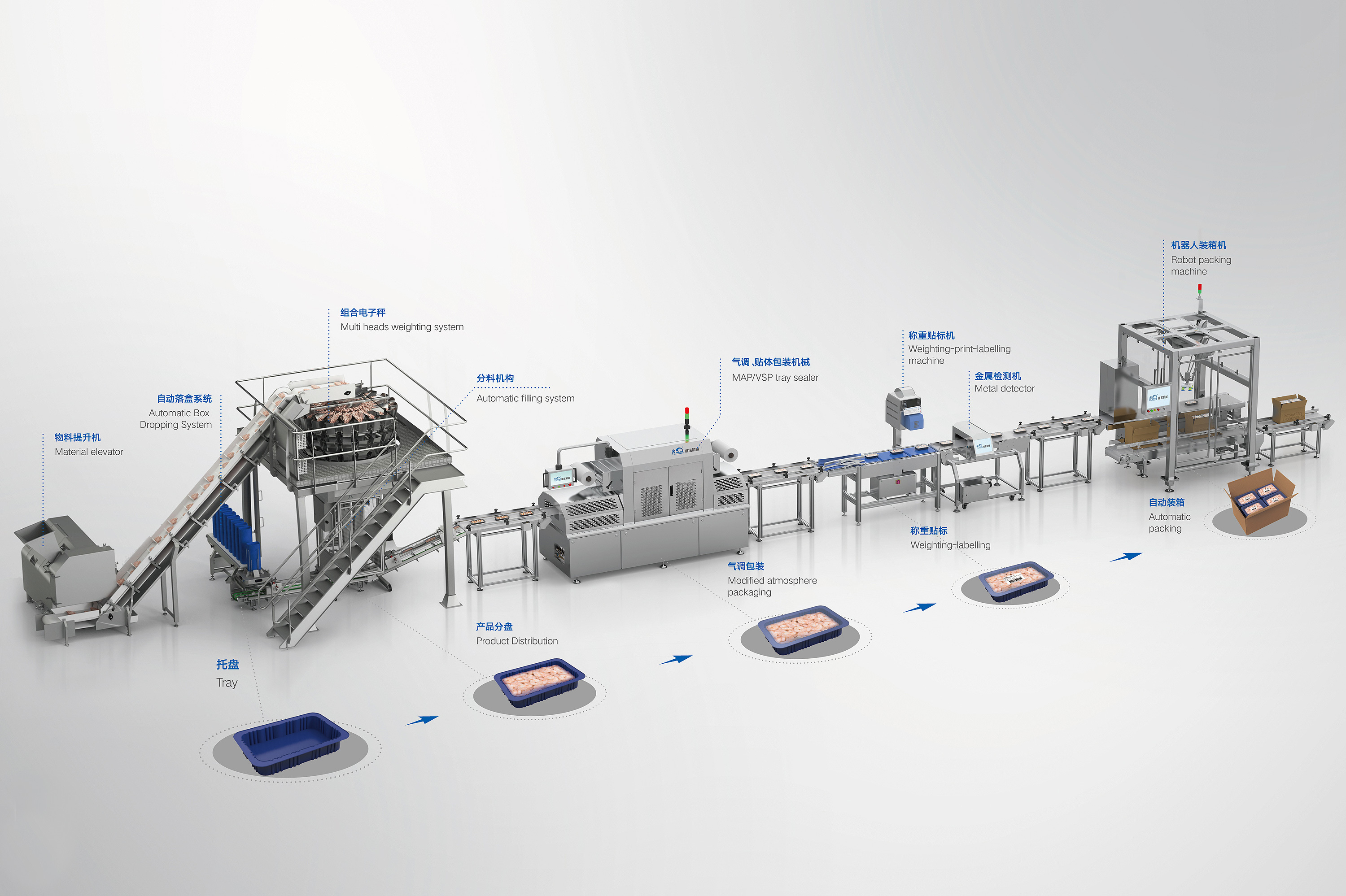

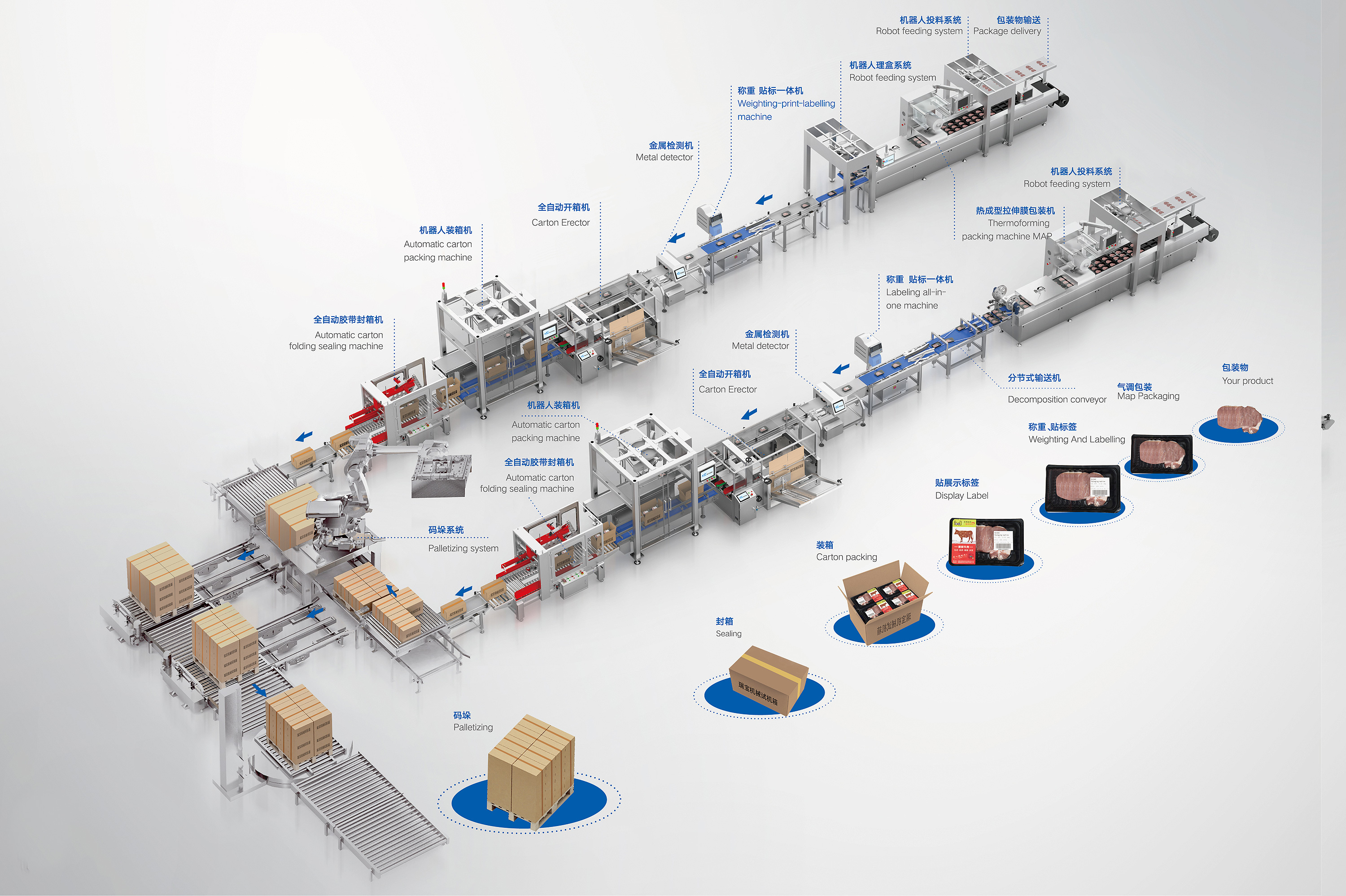

• Thermoformed modified atmosphere packagingFirst, the roll film sheet is stretched to automatically thermoform the packaging box. After filling and placing materials, the processes of air-conditioning sealing, automatic slitting and output of finished packaging products are automatically completed at one time. We use the first vacuum after filling the gas packaging, through the replacement of the gas in the packaging to achieve fresh and extend the shelf life of the effect. The whole machine has a high degree of automation, simple operation, low defective rate, and improved production efficiency.

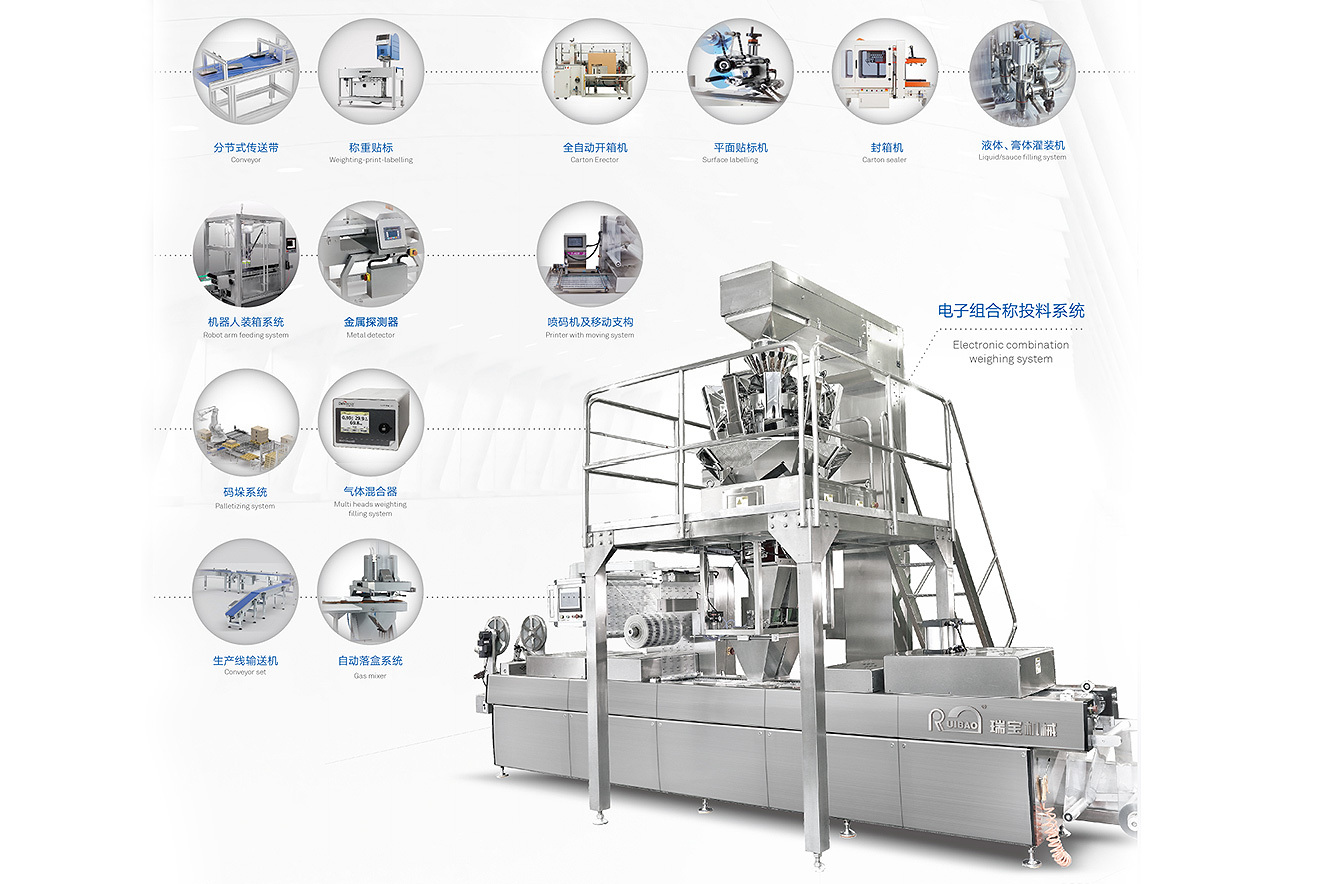

At the same time, the packaging machine can be equipped with various third-party auxiliary equipment such as: manipulator, automatic filling equipment, combination weighing, inkjet printer, labeling machine, metal detection, packing, sealing, palletizing, etc. Automated packaging can greatly save manpower.

Machine Features

• Adopt Japan Mitsubishi PLC control system, fault alarm system.

• Automatic thermoforming, can save costs and improve production efficiency.

• Personalized customization, customized packaging solutions according to packaging requirements.

• Security, all functional partitions are covered by stainless steel protective covers to prevent burns and pinching.

• The combination of mold, easy to replace, a multi-purpose machine.

The punching system can ensure that the edges of the packaging box are cut smoothly without adhesion.

Thermoformed stretch film vacuum packaging machine

| Model | DLZ-320MP | DLZ-420MP | DLZ-520MP |

| Upper film width | 295mm | 395mm | 495mm |

| Lower film width | 322mm | 422mm | 522mm |

| Forming depth | ≤100mm | ≤ 120mm | ≤ 150mm |

| Power Supply/Power | 13 ~ 18KW 380v(220v)50/60HZ (optional) | ||

| Packing rate | 4~5 cycles/min | 4~6 cycles/min | 5~8 cycles/min |

| Packing shape |  |

||

| Overall dimension | 5380*965*1880mm | 6150*1080*1880mm | 6200*1180*1880mm |

| Weight | 1820kg | 2200kg | 2400kg |

| packing form | Hot film forming packaging | ||

| Gas environment | modified atmosphere | ||

| Opening aid | Easy tear angle (optional) | ||

| Codes | Optional | ||

| filling machine | Optional | ||

| Configuration | |||

| Vacuum pump | BUSCH (Germany) | ||

| Electrical components | SCHNEIDER (Schneider, France) | ||

| Pneumatic components | SMC (Japan). Yadke (Taiwan) | ||

| Touch screen | SIEMENS (Siemens, Germany) | ||

| Servo motor | MITSUBISH (Mitsubishi, Japan) | ||

\

\

Leave us a message

SAF Coolest v1.3.1.1 设置面板 HMZSX-ZXJW-OQAQE-AAA

无数据提示

Sorry, the current column is being updated, stay tuned!

You can look at other columns or go backHome Page